Page 34 - MILLING_CATALOG_INCH_2022_P93-P228

P. 34

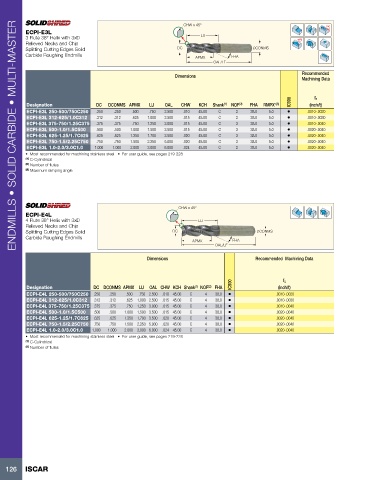

CHW x 45° Rd°

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECPI-E3L

3 Flute 38° Helix with 3xD LU

Relieved Necks and Chip

Splitting Cutting Edges Solid DC DCONMS

Carbide Roughing Endmills APMX FHA

OAL/LF

Dimensions Recommended

Machining Data

IC900 fz

Designation DC DCONMS APMX LU OAL CHW KCH Shank (1) NOF (2) FHA RMPX° (3) (inch/t)

ECPI-E3L 250-500/750C250 .250 .250 .500 .750 2.500 .010 45.00 C 3 38.0 5.0 • .0010-.0020

ECPI-E3L 312-625/1.0C312 .312 .312 .625 1.000 2.500 .015 45.00 C 3 38.0 5.0 • .0010-.0030

ECPI-E3L 375-750/1.25C375 .375 .375 .750 1.250 3.000 .015 45.00 C 3 38.0 5.0 • .0010-.0040

ECPI-E3L 500-1.0/1.5C500 .500 .500 1.000 1.500 3.500 .015 45.00 C 3 38.0 5.0 • .0020-.0040

ECPI-E3L 625-1.25/1.7C625 .625 .625 1.250 1.700 3.500 .020 45.00 C 3 38.0 5.0 • .0020-.0040

ECPI-E3L 750-1.5/2.25C750 .750 .750 1.500 2.250 5.000 .020 45.00 C 3 38.0 5.0 • .0020-.0040

ECPI-E3L 1.0-2.0/3.0C1.0 1.000 1.000 2.000 3.000 6.000 .024 45.00 C 3 38.0 5.0 • .0020-.0040

• Most recommended for machining stainless steel • For user guide, see pages 219-228

(1) C-Cylindrical

(2) Number of flutes

(3) Maximum ramping angle

CHW x 45°

ECPI-E4L

4 Flute 38° Helix with 3xD LU

Relieved Necks and Chip

Splitting Cutting Edges Solid DC DCONMS

Carbide Roughing Endmills

APMX FHA

OAL/LF

Dimensions Recommended Machining Data

IC900 fz

Designation DC DCONMS APMX LU OAL CHW KCH Shank (1) NOF (2) FHA (inch/t)

ECPI-E4L 250-500/750C250 .250 .250 .500 .750 2.500 .010 45.00 C 4 38.0 • .0010-.0020

ECPI-E4L 312-625/1.0C312 .312 .312 .625 1.000 2.500 .015 45.00 C 4 38.0 • .0010-.0030

ECPI-E4L 375-750/1.25C375 .375 .375 .750 1.250 3.000 .015 45.00 C 4 38.0 • .0010-.0040

ECPI-E4L 500-1.0/1.5C500 .500 .500 1.000 1.500 3.500 .015 45.00 C 4 38.0 • .0020-.0040

ECPI-E4L 625-1.25/1.7C625 .625 .625 1.250 1.700 3.500 .020 45.00 C 4 38.0 • .0020-.0040

ECPI-E4L 750-1.5/2.25C750 .750 .750 1.500 2.250 5.000 .020 45.00 C 4 38.0 • .0020-.0040

ECPI-E4L 1.0-2.0/3.0C1.0 1.000 1.000 2.000 3.000 6.000 .024 45.00 C 4 38.0 • .0020-.0040

• Most recommended for machining stainless steel • For user guide, see pages 219-228

(1) C-Cylindrical

(2) Number of flutes

126 ISCAR