Page 36 - MILLING_CATALOG_INCH_2022_P93-P228

P. 36

RE Rd°

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

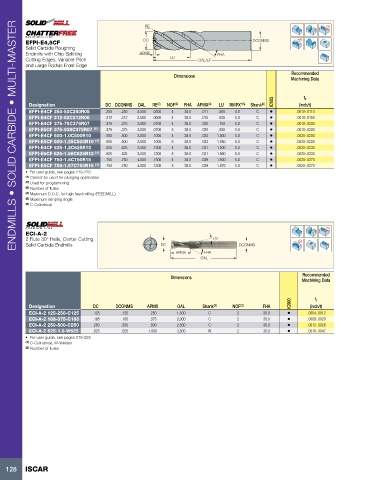

EFPI-E4,5CF DC DCONMS

Solid Carbide Roughing

Endmills with Chip Splitting APMX FHA

Cutting Edges, Variable Pitch LU OAL/LF

and Large Radius Front Edge

Dimensions Recommended

Machining Data

IC903 fz

Designation DC DCONMS OAL RE (2) NOF (3) FHA APMX (4) LU RMPX° (5) Shank (6) (inch/t)

EFPI-E4CF 250-50C250R05 .250 .250 2.500 .0500 4 38.0 .011 .500 5.0 C • .0010-.0110

EFPI-E4CF 312-62C312R06 .312 .312 2.500 .0600 4 38.0 .015 .625 5.0 C • .0010-.0150

EFPI-E4CF 375-75C375R07 .375 .375 3.000 .0700 4 38.0 .020 .750 5.0 C • .0010-.0200

EFPI-E5CF 375-938C375R07 (1) .375 .375 3.000 .0700 5 38.0 .020 .938 5.0 C • .0010-.0200

EFPI-E4CF 500-1.0C500R10 .500 .500 3.000 .1000 4 38.0 .023 1.000 5.0 C • .0020-.0200

EFPI-E5CF 500-1.25C500R10 (1) .500 .500 3.000 .1000 5 38.0 .023 1.250 5.0 C • .0020-.0200

EFPI-E4CF 625-1.2C625R13 .625 .625 3.500 .1300 4 38.0 .031 1.200 5.0 C • .0020-.0230

EFPI-E5CF 625-1.56C625R13 (1) .625 .625 3.500 .1300 5 38.0 .031 1.560 5.0 C • .0020-.0230

EFPI-E4CF 750-1.5C750R15 .750 .750 4.000 .1500 4 38.0 .039 1.500 5.0 C • .0020-.0270

EFPI-E5CF 750-1.87C750R15 (1) .750 .750 4.000 .1500 5 38.0 .039 1.870 5.0 C • .0020-.0270

• For user guide, see pages 219-228

(1) Cannot be used for plunging application

(2) Used for programming

(3) Number of flutes

(4) Maximum D.O.C. for high feed milling (FEEDMILL)

(5) Maximum ramping angle

(6) C-Cylindrical

Rd°

ECI-A-2

2 Flute 30° Helix, Center Cutting 15°

Solid Carbide Endmills DC DCONMS

APMX FHA

OAL

Recommended

Dimensions Machining Data

IC900 fz

Designation DC DCONMS APMX OAL Shank (1) NOF (2) FHA (inch/t)

ECI-A-2 125-250-C125 .125 .125 .250 1.500 C 2 30.0 • .0004-.0012

ECI-A-2 188-375-C188 .188 .188 .375 2.000 C 2 30.0 • .0008-.0020

ECI-A-2 250-500-C250 .250 .250 .500 2.500 C 2 30.0 • .0012-.0028

ECI-A-2 625-1.0-W625 .625 .625 1.000 3.500 W 2 30.0 • .0016-.0047

• For user guide, see pages 219-228

(1) C-Cylindrical, W-Weldon

(2) Number of flutes

128 ISCAR