Page 39 - NEW_PRODUCT_CATALOG_2022

P. 39

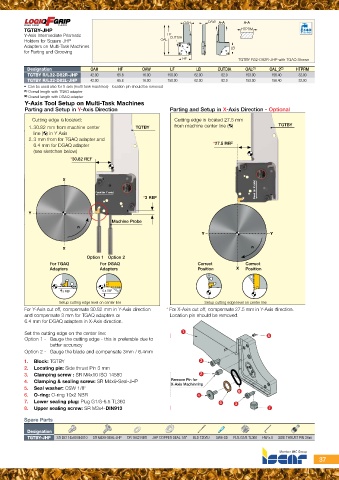

OAH OAW A-A A-A

TGTBY-JHP HTPRM

Y-Axis Intermediate Prismatic LF CUTDIA Bar Max

Holders for Square JHP OAL

Adapters on Multi-Task Machines LB

for Parting and Grooving

HF TGTBY R32-D82R-JHP with TGAQ Shown

Designation OAH HF OAW LF LB CUTDIA OAL (1) OAL_2 (2) HTPRM

TGTBY R/L32-D82R-JHP 42.00 65.8 16.00 150.00 62.00 82.0 153.00 156.40 32.00

TGTBY R/L32-D82L-JHP 42.00 65.8 16.00 150.00 62.00 82.0 153.00 156.40 32.00

• Can be used also for X-axis (multi-task machines) - location pin should be removed

(1) Overall length with TGAQ adapter

(2) Overall length with DGAQ adapter

Y-Axis Tool Setup on Multi-Task Machines

Parting and Setup in Y-Axis Direction Parting and Setup in X-Axis Direction - Optional

Cutting edge is located: Cutting edge is located 27.5 mm

1. 30.82 mm from machine center TGTBY from machine center line ( ) TGTBY

line ( ) in Y Axis

2. 3 mm from for TGAQ adapter and

6.4 mm for DGAQ adapter *27.5 REF

(see sketches below)

*30.82 REF

X

Feed (in X axis)

Feed (in Y axis)

*3 REF

Y

Machine Probe

n

Y Y

X n

Option 1 Option 2

For TGAQ For DGAQ Correct Correct

Adapters Adapters Position X Position

3 REF 6.4 REF

Setup cutting edge level on center line Setup cutting edge level on center line

* For Y-Axis cut off, compensate 30.82 mm in Y-Axis direction * For X-Axis cut off, compensate 27.5 mm in Y-Axis direction.

and compensate 3 mm for TGAQ adapters or Location pin should be removed.

6.4 mm for DGAQ adapters in X-Axis direction.

Set the cutting edge on the center line: 1 8

Option 1 - Gauge the cutting edge - this is preferable due to

better accuracy

Option 2 - Gauge the blade and compensate 3mm / 6.4mm

1. Block: TGTBY 3

2. Locating pin: Side thrust Pin 3 mm

3. Clamping screw : SR M4x10 ISO 14580 2

4. Clamping & sealing screw: SR M4x9-Seal-JHP Remove Pin for

X-Axis Machinning

5. Seal washer: CSW 1/8’’ 6

6. O-ring: O-ring 10x2 NBR 4

7. Lower sealing plug: Plug G1/8-6.5 TL360 5 3

8. Upper sealing screw: SR M3x4-DIN913 7

Spare Parts

Designation

TGTBY-JHP SR ISO 14580 M4X10 SR M4X9-SEAL-JHP OR 16X2 NBR JHP COPPER SEAL 1/8" BLD T20/S7 SW6-SD PLG G1/8 TL360 HW 5.0 SIDE THRUST PIN 3mm

37