Page 100 - Turning_catalog_INCH_2022_45_P509-690

P. 100

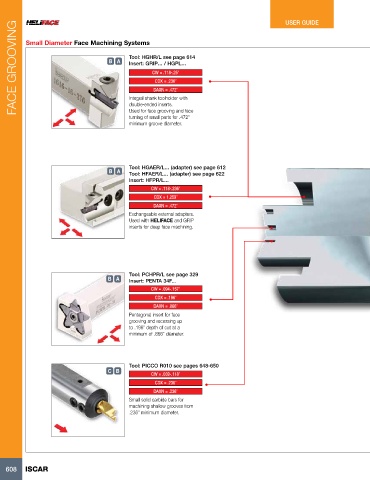

FACE GROOVING Small Diameter Face Machining Systems CW = .118-.25” USER GUIDE

Tool: HGHR/L see page 614

B

A

Insert: GRIP… / HGPL…

CDX = .236”

DAXN = .472”

Integral shank toolholder with

double-ended inserts.

Used for face grooving and face

turning of small parts for .472”

minimum groove diameter.

Tool: HGAER/L… (adapter) see page 612

B A Tool: HFAER/L… (adapter) see page 622

Insert: HFPR/L…

CW = .118-.236”

CDX = 1.259”

DAXN = .472”

Exchangeable external adapters.

Used with HELIFACE and GRIP

inserts for deep face machining.

Tool: PCHPR/L see page 329

B A Insert: PENTA 34F...

CW = .094-.157”

CDX = .196”

DAXN = .866”

Pentagonal insert for face

grooving and recessing up

to .196” depth of cut at a

minimum of .866” diameter.

Tool: PICCO R010 see pages 648-650

C B

CW = .039-.118”

CDX = .236”

DAXN = .236”

Small solid carbide bars for

machining shallow grooves from

.236” minimum diameter.

608 ISCAR