Page 30 - Turning_catalog_INCH_2022_45_P691-914

P. 30

Continued PDX PDX

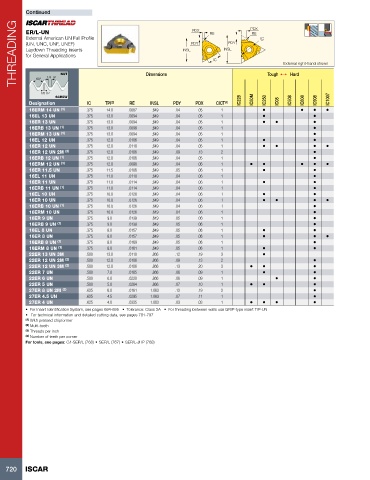

THREADING External American UN Full Profile INSL PDY RE IC INSL RE IC External right-hand shown

ER/L-UN

(UN, UNC, UNF, UNEF)

PDY

Laydown Threading Inserts

for General Applications

60°

1/8 TP 1/4 TP NUT Dimensions Tough 1 Hard

SCREW

Designation IC TPI (3) RE INSL PDY PDX CICT (4) IC228 IC50M IC250 IC08 IC508 IC808 IC908 IC1007

16ERM 14 UN (1) .375 14.0 .0087 .649 .04 .05 1 • • • •

16EL 13 UN .375 13.0 .0094 .649 .04 .05 1 • •

16ER 13 UN .375 13.0 .0094 .649 .04 .05 1 • • •

16ERB 13 UN (1) .375 13.0 .0098 .649 .04 .05 1 •

16ERM 13 UN (1) .375 13.0 .0094 .649 .04 .05 1 •

16EL 12 UN .375 12.0 .0106 .649 .04 .05 1 • •

16ER 12 UN .375 12.0 .0118 .649 .04 .05 1 • • • •

16ER 12 UN 2M (2) .375 12.0 .0106 .649 .09 .13 2 •

16ERB 12 UN (1) .375 12.0 .0106 .649 .04 .05 1 •

16ERM 12 UN (1) .375 12.0 .0098 .649 .04 .06 1 • • • • •

16ER 11.5 UN .375 11.5 .0106 .649 .05 .06 1 • •

16EL 11 UN .375 11.0 .0110 .649 .04 .06 1 •

16ER 11 UN .375 11.0 .0114 .649 .04 .06 1 • •

16ERB 11 UN (1) .375 11.0 .0114 .649 .04 .06 1 •

16EL 10 UN .375 10.0 .0126 .649 .04 .06 1 • •

16ER 10 UN .375 10.0 .0126 .649 .04 .06 1 • • • •

16ERB 10 UN (1) .375 10.0 .0126 .649 .04 .06 1 •

16ERM 10 UN .375 10.0 .0126 .649 .04 .06 1 •

16ER 9 UN .375 9.0 .0138 .649 .05 .06 1 •

16ERB 9 UN (1) .375 9.0 .0138 .649 .05 .06 1 •

16EL 8 UN .375 8.0 .0157 .649 .05 .06 1 • •

16ER 8 UN .375 8.0 .0157 .649 .05 .06 1 • • •

16ERB 8 UN (1) .375 8.0 .0169 .649 .05 .06 1 •

16ERM 8 UN (1) .375 8.0 .0161 .649 .05 .06 1 • •

22ER 13 UN 3M .500 13.0 .0110 .866 .12 .19 3 •

22ER 12 UN 2M (2) .500 12.0 .0106 .866 .09 .13 2 •

22ER 12 UN 3M (2) .500 12.0 .0106 .866 .13 .20 3 • • •

22ER 7 UN .500 7.0 .0185 .866 .06 .09 1 • •

22ER 6 UN .500 6.0 .0220 .866 .06 .09 1 • •

22ER 5 UN .500 5.0 .0264 .866 .07 .10 1 • • •

27ER 8 UN 2M (2) .625 8.0 .0161 1.083 .12 .19 2 •

27ER 4.5 UN .625 4.5 .0295 1.083 .07 .11 1 •

27ER 4 UN .625 4.0 .0335 1.083 .03 .03 1 • • • •

• For Insert Identification System, see pages 694-695 • Tolerance: Class 2A • For threading between walls use GRIP-type insert TIP-UN

• For technical information and detailed cutting data, see pages 781-797

(1) With pressed chipformer

(2) Multi-tooth

(3) Threads per inch

(4) Number of teeth per corner

For tools, see pages: C#-SER/L (768) • SER/L (767) • SER/L-JHP (768)

720 ISCAR