Page 94 - Turning_catalog_INCH_2022_45_P691-914

P. 94

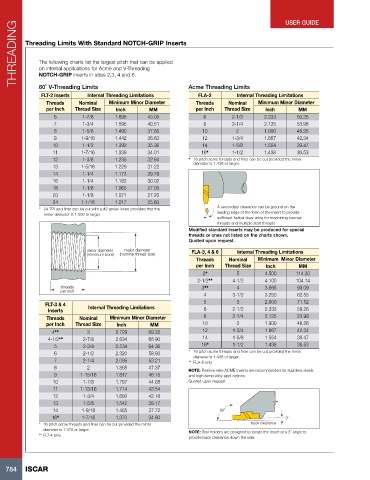

THREADING Threading Limits With Standard NOTCH-GRIP Inserts USER GUIDE

The following charts list the largest pitch that can be applied

on internal applications for Acme and V-Threading

NOTCH-GRIP inserts in sizes 2,3, 4 and 6.

60˚ V-Threading Limits

FLT-2 Inserts Internal Threading Limitations Acme Threading Limits

FLA-2

Internal Threading Limitations

Threads Nominal Minimum Minor Diameter Threads Nominal Minimum Minor Diameter

per Inch Thread Size Inch MM per Inch Thread Size Inch MM

6 1-7/8 1.695 43.05 6 2-1/2 2.333 59.26

7 1-3/4 1.595 40.51 8 2-1/4 2.125 53.98

8 1-5/8 1.490 37.85 10 2 1.900 48.26

9 1-9/16 1.442 36.63 12 1-3/4 1.667 42.34

10 1-1/2 1.392 35.36 14 1-5/8 1.554 39.47

11 1-7/16 1.339 34.01 16* 1-1/2 1.438 36.53

12 1-3/8 1.285 32.64 * 16 pitch acme threads and finer can be cut provided the minor

13 1-5/16 1.229 31.22 diameter is 1.438 or larger.

14 1-1/4 1.173 29.79

16 1-1/4 1.182 30.02

18 1-1/8 1.065 27.05

20 1-1/8 1.071 27.20

24 1-1/16 1.017 25.83

* 24 TPI and finer can be cut with a #2 series insert provided that the A secondary clearance can be ground on the

minor diameter is 1.000 or larger. leading edge of the form of the insert to provide

sufficient helical clear ance for machining courser

threads and multiple start threads

Modified standard inserts may be produced for special

threads or ones not listed on the charts shown.

Quoted upon request.

minor diameter major diameter FLA-3, 4 & 6 Internal Threading Limitations

(minimum bore) (nominal thread size)

Threads Nominal Minimum Minor Diameter

per Inch Thread Size Inch MM

2* 5 4.500 114.30

2-1/2** 4-1/2 4.100 104.14

threads 3** 4 3.665 93.09

per inch

4 3-1/2 3.250 82.55

FLT-3 & 4 Internal Threading Limitations 5 3 2.800 71.12

Inserts 6 2-1/2 2.333 59.26

Threads Nominal Minimum Minor Diameter 8 2-1/4 2.125 23.98

per Inch Thread Size Inch MM 10 2 1.900 48.26

4** 3 2.729 69.32 12 1-3/4 1.667 42.34

4-1/2** 2-7/8 2.634 66.90 14 1-5/8 1.554 39.47

5 2-3/4 2.534 64.36 16* 1-1/2 1.438 36.53

6 2-1/2 2.320 58.93 * 16 pitch acme threads and finer can be cut provided the minor

diameter is 1.438 or larger.

7 2-1/4 2.095 53.21 ** FLA-6 only.

8 2 1.865 47.37 NOTE: Positive rake ACME inserts are recommended for stainless steels

9 1-15/16 1.817 46.15 and high-temp alloy appl cations.

10 1-7/8 1.767 44.88 Quoted upon request.

11 1-13/16 1.714 43.54

12 1-3/4 1.660 42.16

13 1-5/8 1.542 39.17

14 1-9/16 1.485 37.72 90˚

16* 1-7/16 1.370 34.80 3˚

* 16 pitch acme threads and finer can be cut provided the minor back clearance

diameter is 1.370 or larger. NOTE: Tool holders are designed to locate the insert at a 3˚ angle to

** FLT-4 only.

provide back clearance down the side.

784 ISCAR