Page 123 - THREADING CATALOG

P. 123

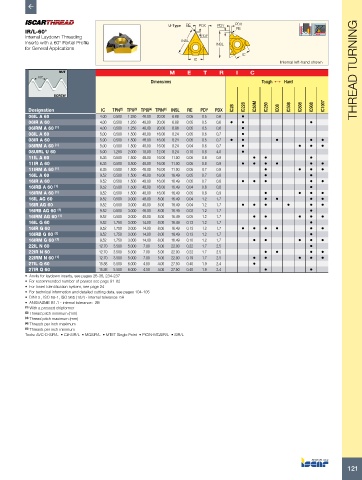

U-Type RE PDX PDY PDX

IR/L-60° RE

Internal Laydown Threading PDY

Inserts with a 60° Partial Profile lNSL lNSL

for General Applications

IC

IC

Internal left-hand shown

NUT M E T R I C THREAD TURNING

60°

Dimensions Tough 1 Hard

SCREW

Designation IC TPN (2) TPX (3) TPIX (4) TPIN (5) INSL RE PDY PDX IC28 IC228 IC50M IC250 IC08 IC508 IC808 IC908 IC1007

06IL A 60 4.00 0.500 1.250 48.00 20.00 6.88 0.05 0.5 0.6 •

06IR A 60 4.00 0.500 1.250 48.00 20.00 6.88 0.05 0.5 0.6 • • •

06IRM A 60 (1) 4.00 0.500 1.250 48.00 20.00 6.88 0.05 0.5 0.6 •

08IL A 60 5.00 0.500 1.500 48.00 16.00 8.24 0.05 0.6 0.7 •

08IR A 60 5.00 0.500 1.500 48.00 16.00 8.24 0.05 0.5 0.7 • • • • •

08IRM A 60 (1) 5.00 0.500 1.500 48.00 16.00 8.24 0.04 0.6 0.7 • • • •

08UIRL U 60 5.00 1.250 2.000 18.00 12.00 8.24 0.10 0.8 4.0 •

11IL A 60 6.35 0.500 1.500 48.00 16.00 11.00 0.05 0.8 0.9 • • •

11IR A 60 6.35 0.500 0.500 48.00 16.00 11.00 0.05 0.8 0.9 • • • • • •

11IRM A 60 (1) 6.35 0.500 1.500 48.00 16.00 11.00 0.05 0.7 0.9 • • • •

16IL A 60 9.52 0.500 1.500 48.00 16.00 16.49 0.05 0.7 0.8 • •

16IR A 60 9.52 0.500 1.500 48.00 16.00 16.49 0.05 0.7 0.8 • • • • •

16IRB A 60 (1) 9.52 0.500 1.500 48.00 16.00 16.49 0.04 0.8 0.8 •

16IRM A 60 (1) 9.52 0.500 1.500 48.00 16.00 16.49 0.05 0.8 0.9 • • • •

16IL AG 60 9.52 0.500 3.000 48.00 8.00 16.49 0.04 1.2 1.7 • • • •

16IR AG 60 9.52 0.500 3.000 48.00 8.00 16.49 0.04 1.2 1.7 • • • • • •

16IRB AG 60 (1) 9.52 0.500 3.000 48.00 8.00 16.49 0.03 1.2 1.7 •

16IRM AG 60 (1) 9.52 0.500 3.000 48.00 8.00 16.49 0.05 1.2 1.7 • • • • •

16IL G 60 9.52 1.750 3.000 14.00 8.00 16.49 0.13 1.2 1.7 •

16IR G 60 9.52 1.750 3.000 14.00 8.00 16.49 0.13 1.2 1.7 • • • • • •

16IRB G 60 (1) 9.52 1.750 3.000 14.00 8.00 16.49 0.13 1.2 1.7 •

16IRM G 60 (1) 9.52 1.750 3.000 14.00 8.00 16.49 0.10 1.2 1.7 • • • • •

22IL N 60 12.70 3.500 5.000 7.00 5.00 22.00 0.22 1.7 2.5 •

22IR N 60 12.70 3.500 5.000 7.00 5.00 22.00 0.22 1.7 2.5 • • • •

22IRM N 60 (1) 12.70 3.500 5.000 7.00 5.00 22.00 0.19 1.7 2.5 • • • • •

27IL Q 60 15.88 5.500 6.000 4.50 4.00 27.50 0.40 1.9 2.4 •

27IR Q 60 15.88 5.500 6.000 4.50 4.00 27.50 0.40 1.9 2.4 • •

• Anvils for laydown inserts, see pages 26-35, 234-237

• For recommended number of passes see page 81-82

• For Insert Identification system, see page 24

• For technical information and detailed cutting data, see pages 104-105

• DIN13 , ISO 68-1, ISO 965 (1&2) - internal tolerance: 6H

• ANSI/ASME B1.1 - internal tolerance: 2B

(1) With a pressed chipformer

(2) Thread pitch minimum (mm)

(3) Thread pitch maximum (mm)

(4) Threads per inch maximum

(5) Threads per inch minimum

Tools: AVC-D-SIR/L • C#-SIR/L • MGSIR/L • MTET Single Point • PICIN-MGSIR/L • SIR/L

121