Page 285 - THREADING CATALOG

P. 285

USER GUIDE

Selecting Endmill Outer Diameter for Best Effect

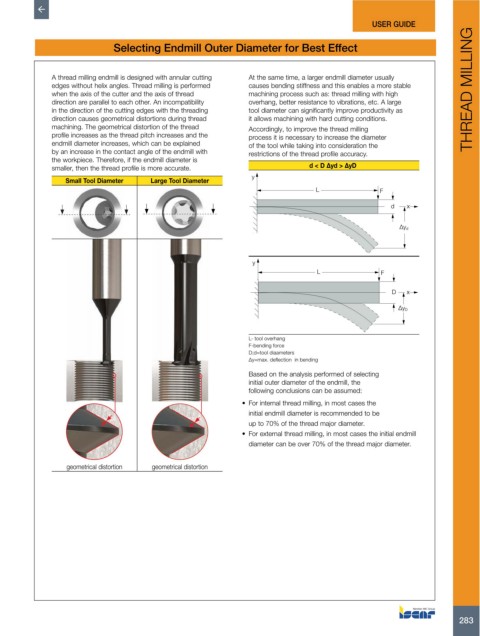

A thread milling endmill is designed with annular cutting At the same time, a larger endmill diameter usually

edges without helix angles. Thread milling is performed causes bending stiffness and this enables a more stable

when the axis of the cutter and the axis of thread machining process such as: thread milling with high THREAD MILLING

direction are parallel to each other. An incompatibility overhang, better resistance to vibrations, etc. A large

in the direction of the cutting edges with the threading tool diameter can significantly improve productivity as

direction causes geometrical distortions during thread it allows machining with hard cutting conditions.

machining. The geometrical distortion of the thread Accordingly, to improve the thread milling

profile increases as the thread pitch increases and the process it is necessary to increase the diameter

endmill diameter increases, which can be explained of the tool while taking into consideration the

by an increase in the contact angle of the endmill with restrictions of the thread profile accuracy.

the workpiece. Therefore, if the endmill diameter is

smaller, then the thread profile is more accurate. d < D Δyd > ΔyD

y y

Small Tool Diameter Large Tool Diameter

L F

d x

∆y d

y

L F

D x

∆y D

L- tool overhang

F-bending force

D;d=tool diaameters

Δy=max. deflection in bending

Based on the analysis performed of selecting

initial outer diameter of the endmill, the

following conclusions can be assumed:

• For internal thread milling, in most cases the

initial endmill diameter is recommended to be

up to 70% of the thread major diameter.

• For external thread milling, in most cases the initial endmill

diameter can be over 70% of the thread major diameter.

geometrical distortion geometrical distortion

283