Page 316 - THREADING CATALOG

P. 316

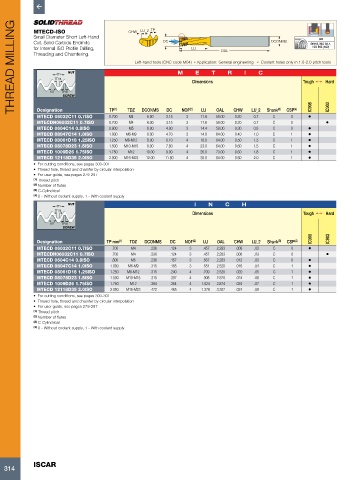

THREAD MILLING MTECD-ISO NUT CHW Left-hand tools (CNC code M04) • Application: General engineering • Coolant holes only in 1.0-2.0 pitch tools

TP

LU_2

Small Diameter Short Left-Hand

6H

DC

DCONMS

Cut. Solid Carbide Endmills

DIN13, ISO 68-1,

ISO 965 (1&2)

for Internal ISO Profile Drilling,

LU

OAL

Threading and Chamfering.

M

R

C

T

I

E

TP

TP/4

Tough 1 Hard

Dimensions

60˚

TP/8

SCREW

Designation

DC

LU

MTECD 06032C11 0.7ISO TP (1) TDZ DCONMS 3.15 NOF (2) 11.6 OAL CHW LU_2 Shank (3) CSP (4) • IC908 IC903

0.20

58.00

0.700

0

C

0.7

M4

3

6.00

MTECDH06032C11 0.7ISO 0.700 M4 6.00 3.15 3 11.6 58.00 0.20 0.7 C 0 •

MTECD 0604C14 0.8ISO 0.800 M5 6.00 4.00 3 14.4 58.00 0.30 0.8 C 0 •

MTECD 08047C14 1.0ISO 1.000 M6-M9 8.00 4.70 3 14.0 64.00 0.40 1.0 C 1 •

MTECD 08061D18 1.25ISO 1.250 M8-M12 8.00 6.10 4 18.0 64.00 0.50 1.3 C 1 •

MTECD 08078D23 1.5ISO 1.500 M10-M15 8.00 7.80 4 23.0 64.00 0.60 1.5 C 1 •

MTECD 1009D26 1.75ISO 1.750 M12 10.00 9.00 4 26.0 73.00 0.60 1.8 C 1 •

MTECD 12118D35 2.0ISO 2.000 M16-M23 12.00 11.80 4 35.0 84.00 0.60 2.0 C 1 •

• For cutting conditions, see pages 300-301

• Thread hole, thread and chamfer by circular interpolation

• For user guide, see pages 279-297

(1) Thread pitch

(2) Number of flutes

(3) C-Cylindrical

(4) 0 - Without coolant supply, 1 - With coolant supply

NUT I N C H

TP

TP/4

Dimensions Tough 1 Hard

60˚ TP/8

SCREW

IC908 IC903

Designation TP mm (1) TDZ DCONMS DC NOF (2) LU OAL CHW LU_2 Shank (3) CSP (4)

MTECD 06032C11 0.7ISO .700 M4 .236 .124 3 .457 2.283 .008 .03 C 0 •

MTECDH06032C11 0.7ISO .700 M4 .236 .124 3 .457 2.283 .008 .03 C 0 •

MTECD 0604C14 0.8ISO .800 M5 .236 .157 3 .567 2.283 .012 .03 C 0 •

MTECD 08047C14 1.0ISO 1.000 M6-M9 .315 .185 3 .551 2.520 .016 .04 C 1 •

MTECD 08061D18 1.25ISO 1.250 M8-M12 .315 .240 4 .709 2.520 .020 .05 C 1 •

MTECD 08078D23 1.5ISO 1.500 M10-M15 .315 .307 4 .906 2.520 .024 .06 C 1 •

MTECD 1009D26 1.75ISO 1.750 M12 .394 .354 4 1.024 2.874 .024 .07 C 1 •

MTECD 12118D35 2.0ISO 2.000 M16-M23 .472 .465 4 1.378 3.307 .024 .08 C 1 •

• For cutting conditions, see pages 300-301

• Thread hole, thread and chamfer by circular interpolation

• For user guide, see pages 279-297

(1) Thread pitch

(2) Number of flutes

(3) C-Cylindrical

(4) 0 - Without coolant supply, 1 - With coolant supply

ISCAR

314