Page 320 - THREADING CATALOG

P. 320

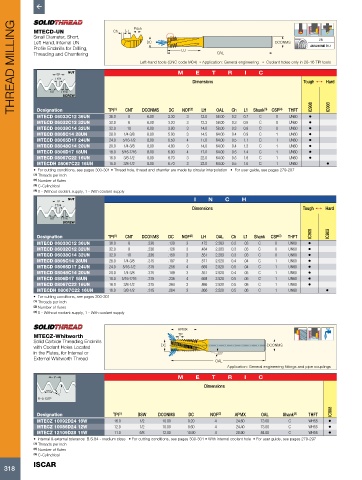

THREAD MILLING MTECD-UN NUT Ch L1 Pitch Left-hand tools (CNC code M04) • Application: General engineering • Coolant holes only in 28-16 TPI tools

Small Diameter, Short,

2B

DCONMS

DC

Left Hand, Internal UN

ANSI/ASME B1.1

Profile Endmills for Drilling,

LU

OAL

Threading and Chamfering

I

E

T

M

C

R

TP

TP/4

Dimensions

Tough 1 Hard

60˚

TP/8

SCREW

Designation

LH

DC

MTECD 06033C12 36UN TPI (1) CNT DCONMS 3.30 NOF (2) 12.0 OAL Ch L1 Shank (3) CSP (4) THFT • IC908 IC903

6.00

C

0.2

58.00

0.7

36.0

8

0

UN60

3

MTECD 06032C12 32UN 32.0 8 6.00 3.20 3 12.3 58.00 0.3 0.8 C 0 UN60 •

MTECD 06038C14 32UN 32.0 10 6.00 3.80 3 14.0 58.00 0.3 0.8 C 0 UN60 •

MTECD 0805C14 28UN 28.0 1/4-3/8 8.00 5.00 3 14.5 64.00 0.4 0.9 C 1 UN60 •

MTECD 08065D17 24UN 24.0 5/16-1/2 8.00 6.50 4 17.0 64.00 0.5 1.1 C 1 UN60 •

MTECD 08048C14 20UN 20.0 1/4-3/8 8.00 4.80 3 14.0 64.00 0.4 1.3 C 1 UN60 •

MTECD 0806D17 18UN 18.0 5/16-7/16 8.00 6.00 4 17.0 64.00 0.5 1.4 C 1 UN60 •

MTECD 08067C22 16UN 16.0 3/8-1/2 8.00 6.70 3 22.0 64.00 0.5 1.6 C 1 UN60 •

MTECDH 08067C22 16UN 16.0 3/8-1/2 8.00 6.70 3 22.0 64.00 0.5 1.6 C 1 UN60 •

• For cutting conditions, see pages 300-301 • Thread hole, thread and chamfer are made by circular interpolation • For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

(4) 0 - Without coolant supply, 1 - With coolant supply

NUT I N C H

TP

TP/4

Dimensions Tough 1 Hard

60˚ TP/8

SCREW

IC908 IC903

Designation TPI (1) CNT DCONMS DC NOF (2) LH OAL Ch L1 Shank CSP (3) THFT

MTECD 06033C12 36UN 36.0 8 .236 .130 3 .472 2.283 0.2 .03 C 0 UN60 •

MTECD 06032C12 32UN 32.0 8 .236 .126 3 .484 2.283 0.3 .03 C 0 UN60 •

MTECD 06038C14 32UN 32.0 10 .236 .150 3 .551 2.283 0.3 .03 C 0 UN60 •

MTECD 0805C14 28UN 28.0 1/4-3/8 .315 .197 3 .571 2.520 0.4 .04 C 1 UN60 •

MTECD 08065D17 24UN 24.0 5/16-1/2 .315 .256 4 .669 2.520 0.5 .04 C 1 UN60 •

MTECD 08048C14 20UN 20.0 1/4-3/8 .315 .189 3 .551 2.520 0.4 .05 C 1 UN60 •

MTECD 0806D17 18UN 18.0 5/16-7/16 .315 .236 4 .669 2.520 0.5 .06 C 1 UN60 •

MTECD 08067C22 16UN 16.0 3/8-1/2 .315 .264 3 .866 2.520 0.5 .06 C 1 UN60 •

MTECDH 08067C22 16UN 16.0 3/8-1/2 .315 .264 3 .866 2.520 0.5 .06 C 1 UN60 •

• For cutting conditions, see pages 300-301

(1) Threads per inch

(2) Number of flutes

(3) 0 - Without coolant supply, 1 - With coolant supply

APMX

MTECZ-Whitworth TP

Solid Carbide Threading Endmills

with Coolant Holes Located DC DCONMS

in the Flutes, for Internal or 15°

External Whitworth Thread

OAL

Application: General engineering fittings and pipe couplings

P M E T R I C

Dimensions

55°

R=0.137P

IC908

Designation TPI (1) BSW DCONMS DC NOF (2) APMX OAL Shank (3) THFT

MTECZ 10092D24 16W 16.0 1/2 10.00 9.20 4 24.60 73.00 C WH55 •

MTECZ 10086D24 12W 12.0 1/2 10.00 8.60 4 24.40 73.00 C WH55 •

MTECZ 12109D28 11W 11.0 5/8 12.00 10.90 4 28.90 84.00 C WH55 •

• internal & external tolerance: B.S.84 - medium class • For cutting conditions, see pages 300-301 • With internal coolant hole • For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

ISCAR

318