Page 325 - THREADING CATALOG

P. 325

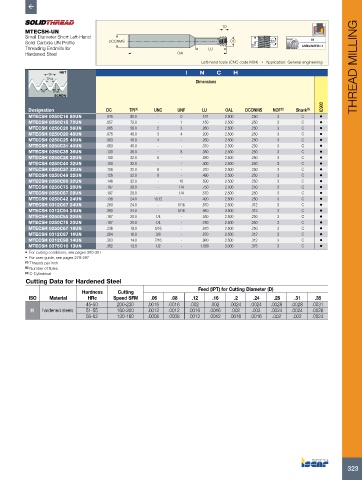

MTECSH-UN TP

Small Diameter Short Left-Hand 2B

Solid Carbide UN Profile DCONMS DC 60°

Threading Endmills for LU TP ANSI/ASME B1.1

Hardened Steel OAL

Left-hand tools (CNC code M04) • Application: General engineering

NUT I N C H THREAD MILLING

TP

TP/4

Dimensions

60˚ TP/8

SCREW

IC903

Designation DC TPI (1) UNC UNF LU OAL DCONMS NOF (2) Shank (3)

MTECSH 0250C16 80UN .045 80.0 - 0 .157 2.500 .250 3 C •

MTECSH 0250C15 72UN .057 72.0 - 1 .150 2.500 .250 3 C •

MTECSH 0250C26 56UN .065 56.0 2 3 .260 2.500 .250 3 C •

MTECSH 0250C20 48UN .075 48.0 3 4 .200 2.500 .250 3 C •

MTECSH 0250C25 40UN .083 40.0 4 - .250 2.500 .250 3 C •

MTECSH 0250C31 40UN .083 40.0 - - .310 2.500 .250 3 C •

MTECSH 0250C35 36UN .130 36.0 - 8 .350 2.500 .250 3 C •

MTECSH 0250C28 32UN .100 32.0 6 - .280 2.500 .250 3 C •

MTECSH 0250C40 32UN .100 32.0 - - .400 2.500 .250 3 C •

MTECSH 0250C37 32UN .126 32.0 8 - .370 2.500 .250 3 C •

MTECSH 0250C49 32UN .126 32.0 8 - .490 2.500 .250 3 C •

MTECSH 0250C59 32UN .146 32.0 - 10 .590 2.500 .250 3 C •

MTECSH 0250C75 28UN .197 28.0 - 1/4 .750 2.500 .250 3 C •

MTECSH 0250C57 28UN .197 28.0 - 1/4 .570 2.500 .250 3 C •

MTECSH 0250C42 24UN .138 24.0 10,12 - .420 2.500 .250 3 C •

MTECSH 0312C67 24UN .260 24.0 - 5/16 .670 2.500 .312 3 C •

MTECSH 0312C94 24UN .260 24.0 - 5/16 .940 2.500 .312 3 C •

MTECSH 0250C55 20UN .187 20.0 1/4 - .550 2.500 .250 3 C •

MTECSH 0250C75 20UN .187 20.0 1/4 - .750 2.500 .250 3 C •

MTECSH 0250C67 18UN .236 18.0 5/16 - .670 2.500 .250 3 C •

MTECSH 0312C87 16UN .264 16.0 3/8 - .870 2.500 .312 3 C •

MTECSH 0312C98 14UN .303 14.0 7/16 - .980 2.500 .312 3 C •

MTECSH 0375C10 13UN .362 13.0 1/2 - 1.080 3.000 .375 3 C •

• For cutting conditions, see pages 300-301

• For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

Cutting Data for Hardened Steel

Feed (IPT) for Cutting Diameter (D)

Hardness Cutting

ISO Material HRc Speed SFM .06 .08 .12 .16 .2 .24 .28 .31 .35

45-50 200-230 .0016 .0016 .002 .002 .0024 .0024 .0028 .0028 .0031

H hardened steels 51-55 160-200 .0012 .0012 .0016 .0016 .002 .002 .0024 .0024 .0028

56-62 130-160 .0008 .0008 .0012 .0012 .0016 .0016 .002 .002 .0024

323