Page 345 - THREADING CATALOG

P. 345

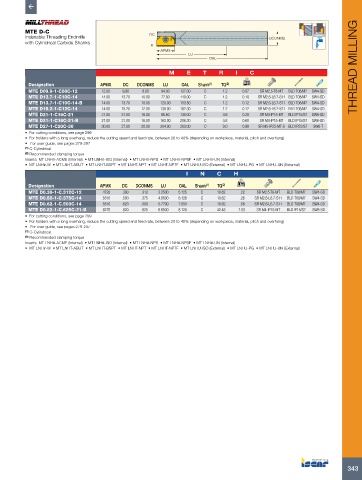

MTE D-C

Indexable Threading Endmills DC DCONMS

with Cylindrical Carbide Shanks

APMX

LU

OAL

M E T R I C THREAD MILLING

Designation APMX DC DCONMS LU OAL Shank (1) TQ (2) kg

MTE D09.9-1-C08C-12 12.00 9.90 8.00 94.00 127.00 C 1.2 0.07 SR M2.5-T8-MT BLD T08/M7 SW4-SD

MTE D13.7-1-C10C-14 14.00 13.70 10.00 77.00 110.00 C 1.2 0.10 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D13.7-1-C10C-14-B 14.00 13.70 10.00 120.00 153.50 C 1.2 0.12 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D15.2-1-C12C-14 14.00 15.20 12.00 139.00 182.30 C 1.2 0.12 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D21-1-C16C-21 21.00 21.00 16.00 86.60 130.00 C 4.8 0.28 SR M4-IP15-MT BLD IP15/S7 SW6-SD

MTE D21-1-C16C-21-B 21.00 21.00 16.00 163.00 206.30 C 4.8 0.60 SR M4-IP15-MT BLD IP15/S7 SW6-SD

MTE D27-1-C20C-30 30.00 27.00 20.00 204.00 263.00 C 9.0 0.99 SR M5-IP25-MT-S BLD IP25/S7 SW6-T

• For cutting conditions, see page 299

• For holders with a long overhang, reduce the cutting speed and feed rate, between 20 to 40% (depending on workpiece, material, pitch and overhang)

• For user guide, see pages 279-297

(1) C-Cylindrical

(2) Recommended clamping torque

Inserts: MT LNH#-ACME (Internal) • MT LNH#-ISO (Internal) • MT LNH#-NPS • MT LNH#-NPSF • MT LNH#-UN (Internal)

• MT LNH#-W • MT LNHT-ABUT • MT LNHT-BSPT • MT LNHT-NPT • MT LNHT-NPTF • MT LNHU-ISO (External) • MT LNHU-PG • MT LNHU-UN (External)

I N C H

Designation APMX DC DCONMS LU OAL Shank (1) TQ (2) Lbs

MTE D0.39-1-C.312C-12 .4720 .390 .312 3.2500 5.125 C 10.62 .22 SR M2.5-T8-MT BLD T08/M7 SW4-SD

MTE D0.50-1-C.375C-14 .5510 .500 .375 4.8500 6.126 C 10.62 .26 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D0.62-1-C.500C-14 .5510 .620 .500 5.7700 7.050 C 10.62 .58 SR M2.6-L6.7-S11 BLD T08/M7 SW4-SD

MTE D0.82-1-C.625C-21-B .8270 .820 .625 6.6500 8.120 C 42.48 1.03 SR M4-IP15-MT BLD IP15/S7 SW6-SD

• For cutting conditions, see page 299

• For holders with a long overhang, reduce the cutting speed and feed rate, between 20 to 40% (depending on workpiece, material, pitch and overhang)

• For user guide, see pages 279-297

(1) C-Cylindrical

(2) Recommended clamping torque

Inserts: MT LNH#-ACME (Internal) • MT LNH#-ISO (Internal) • MT LNH#-NPS • MT LNH#-NPSF • MT LNH#-UN (Internal)

• MT LNH#-W • MT LNHT-ABUT • MT LNHT-BSPT • MT LNHT-NPT • MT LNHT-NPTF • MT LNHU-ISO (External) • MT LNHU-PG • MT LNHU-UN (External)

343