Page 340 - THREADING CATALOG

P. 340

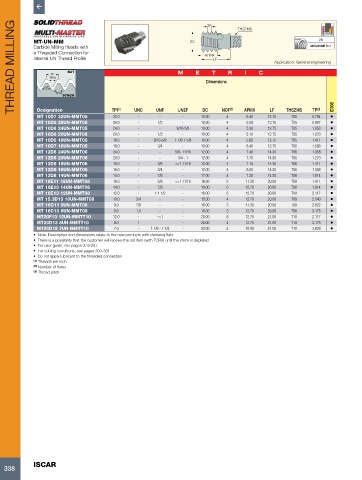

THREAD MILLING MT-UN-MM NUT M DC E APMX T LF R THSZMS C Application: General engineering

TP

2B

ANSI/ASME B1.1

Carbide Milling Heads with

a Threaded Connection for

Internal UN Thread Profile

I

TP

TP/8

Dimensions

60˚

TP/4

SCREW

Designation

LF

DC

MT 10D7 32UN-MMT05 TPI (1) UNC UNF UNEF 10.00 NOF (2) APMX 12.75 THSZMS TP (3) • IC908

-

-

-

32.0

6.40

4

0.794

T05

MT 10D6 28UN-MMT05 28.0 - 1/2 - 10.00 4 5.50 12.75 T05 0.907 •

MT 10D6 24UN-MMT05 24.0 - - 9/16-5/8 10.00 4 5.30 12.75 T05 1.058 •

MT 10D6 20UN-MMT05 20.0 - 1/2 - 10.00 4 5.10 12.75 T05 1.270 •

MT 10D5 18UN-MMT05 18.0 - 9/16-5/8 1 1/8-1 5/8 10.00 4 5.60 12.75 T05 1.411 •

MT 10D7 16UN-MMT05 16.0 - 3/4 - 10.00 4 6.40 12.75 T05 1.588 •

MT 12D8 24UN-MMT06 24.0 - - 5/8- 11/16 12.00 4 7.40 14.30 T06 1.058 •

MT 12D8 20UN-MMT06 20.0 - - 3/4 - 1 12.00 4 7.70 14.30 T06 1.270 •

MT 12D8 18UN-MMT06 18.0 - 5/8 =>1 11/16 12.00 4 7.10 14.30 T06 1.411 •

MT 12D8 16UN-MMT06 16.0 - 3/4 - 12.00 4 8.00 14.30 T06 1.588 •

MT 12D8 14UN-MMT06 14.0 - 7/8 - 12.00 4 7.30 14.30 T06 1.814 •

MT 16E11 18UN-MMT08 18.0 - 5/8 =>1 11/16 16.00 5 11.30 20.00 T08 1.411 •

MT 16E13 14UN-MMT08 14.0 - 7/8 - 16.00 5 12.70 20.00 T08 1.814 •

MT 16E13 12UN-MMT08 12.0 - 1-1 1/2 - 16.00 5 12.70 20.00 T08 2.117 •

MT 15.3D13 10UN-MMT08 10.0 3/4 - - 15.30 4 12.70 20.00 T08 2.540 •

MT 16C11 9UN-MMT08 9.0 7/8 - - 16.00 3 11.30 20.00 T08 2.822 •

MT 16C13 8UN-MMT08 8.0 1.0 - - 16.00 3 12.70 20.00 T08 3.175 •

MT20F13 12UN-MMTT10 12.0 - =>1 - 20.00 6 12.70 21.00 T10 2.117 •

MT20D13 8UN-MMTT10 8.0 1 - 20.00 4 12.70 21.00 T10 3.175 •

MT20D15 7UN-MMTT10 7.0 - 1 1/8 - 1 1/4 - 20.00 4 10.90 21.00 T10 3.629 •

• Note: Description and dimensions relate to the new products with clamping flats

• There is a possibility that the customer will receive the old item (with TORX) until the stock is depleted

• For user guide, see pages 279-297

• For cutting conditions, see pages 300-301

• Do not apply lubricant to the threaded connection

(1) Threads per inch

(2) Number of flutes

(3) Thread pitch

ISCAR

338