Page 394 - THREADING CATALOG

P. 394

USER GUIDE

TAPS General Recommendations (Regrinding)

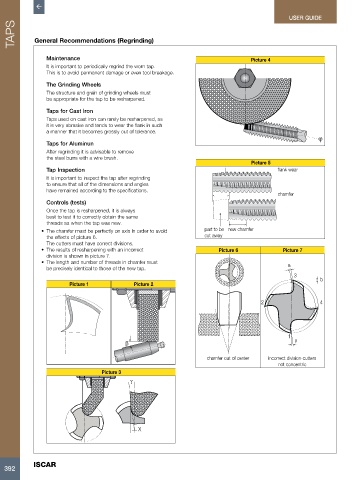

Maintenance Picture 4

It is important to periodically regrind the worn tap.

This is to avoid permanent damage or even tool breakage.

The Grinding Wheels

The structure and grain of grinding wheels must

be appropriate for the tap to be resharpened.

Taps for Cast Iron

Taps used on cast iron can rarely be resharpened, as

it is very abrasive and tends to wear the flank in such

a manner that it becomes grossly out of tolerance.

ϕ

Taps for Aluminun

After regrinding it is advisable to remove

the steel burrs with a wire brush.

Picture 5

Tap Inspection flank wear

It is important to inspect the tap after regrinding

to ensure that all of the dimensions and angles

have remained according to the specifications.

chamfer

Controls (tests)

Once the tap is resharpened, it is always

best to test it to correctly obtain the same

threads as when the tap was new.

• The chamfer must be perfectly on axis in order to avoid part to be new chamfer

the effects of picture 6. cut away

The cutters must have correct divisions.

• The results of resharpening with an incorrect Picture 6 Picture 7

division is shown in picture 7.

• The length and number of threads in chamfer must a

be precisely identical to those of the new tap.

3

b

Picture 1 Picture 2

2 4

1

β γ

chamfer out of center incorrect division-cutters

not concentric

Picture 3

γ

X

ISCAR

392