Page 439 - THREADING CATALOG

P. 439

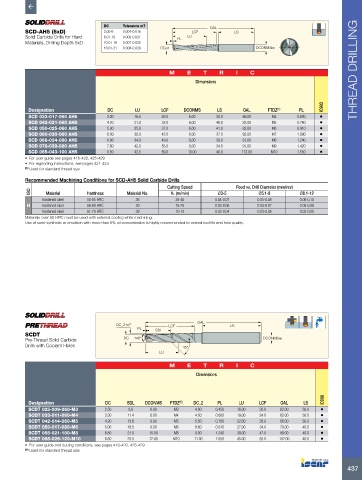

DC Tolerance m7

SCD-AH5 (5xD) 3.00-6 0.004-0.016 LCF OAL LS

Solid Carbide Drills for Hard 6.01-10 0.008-0.021 PL LU

Materials, Drilling Depth 5xD 10.01-18 0.007-0.025

18.01-21 0.008-0.029 DCm7 DCONMSh6

M E T R I C THREAD DRILLING

Dimensions

IC903

Designation DC LU LCF DCONMS LS OAL FTDZ (1) PL

SCD 033-017-060 AH5 3.30 16.5 26.0 6.00 35.0 66.00 M4 0.600 •

SCD 042-021-060 AH5 4.20 21.0 32.0 6.00 46.0 82.00 M5 0.760 •

SCD 050-025-060 AH5 5.00 25.0 37.0 6.00 41.0 82.00 M6 0.910 •

SCD 060-030-060 AH5 6.00 30.0 43.0 6.00 37.0 82.00 M7 1.090 •

SCD 068-034-080 AH5 6.80 34.0 49.0 8.00 39.0 91.00 M8 1.240 •

SCD 078-039-080 AH5 7.80 42.0 55.0 8.00 34.0 91.00 M9 1.420 •

SCD 085-043-100 AH5 8.50 42.5 59.0 10.00 46.0 112.00 M10 1.550 •

• For user guide see pages 416-420, 425-429

• For regrinding instructions, see pages 421-424

(1) Used for standard thread size

Recommended Machining Conditions for SCD-AH5 Solid Carbide Drills

Cutting Speed Feed vs. Drill Diameter (mm/rev)

ISO Material Hardness Material No. Vc (m/min) Ø3-5 Ø5.1-8 Ø8.1-12

hardened steel 50-55 HRC 38 25-40 0.04-0.07 0.05-0.08 0.06-0.10

H hardened steel 56-60 HRC 39 15-25 0.03-0.06 0.04-0.07 0.05-0.08

hardened steel 61-70 HRC 39 10-15 0.02-0.04 0.03-0.05 0.03-0.05

Materials over 50 HRC must be used with external cooling while machining.

Use of semi-synthetic or emulsion with more than 6% oil concentration is highly recommended to extend tool life and hole quality.

DC_2 m7 PL LCF OAL LS

SCDT SDL

Pre-Thread Solid Carbide DC 140° DCONMSh6

Drills with Coolant Holes 45°

LU

M E T R I C

Dimensions

IC908

Designation DC SDL DCONMS FTDZ (1) DC_2 PL LU LCF OAL LS

SCDT 025-009-060-M3 2.50 8.8 6.00 M3 4.00 0.450 16.00 20.0 62.00 36.0 •

SCDT 033-011-060-M4 3.30 11.4 6.00 M4 4.50 0.600 19.00 24.0 62.00 36.0 •

SCDT 042-014-060-M5 4.20 13.6 6.00 M5 5.50 0.760 22.00 28.0 66.00 36.0 •

SCDT 050-017-080-M6 5.00 16.5 8.00 M6 6.60 0.910 27.00 34.0 79.00 40.0 •

SCDT 068-021-100-M8 6.80 21.0 10.00 M8 9.00 1.240 38.00 47.0 89.00 40.0 •

SCDT 085-026-120-M10 8.50 25.5 12.00 M10 11.00 1.550 45.00 55.0 102.00 40.0 •

• For user guide and cutting conditions, see pages 416-420, 425-429

(1) Used for standard thread size

437