Page 56 - THREADING CATALOG

P. 56

USER GUIDE

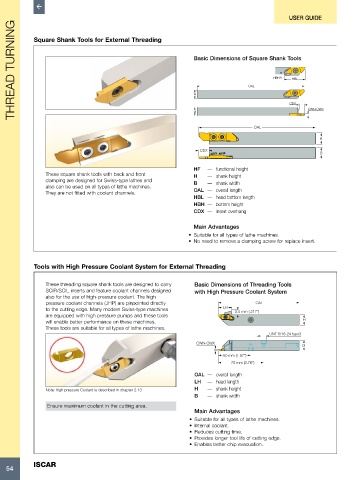

THREAD TURNING Basic Dimensions of Square Shank Tools

Square Shank Tools for External Threading

HBH

HBL

OAL

H

B

OAL CDX CWN-CWX

H

CDX

B

HF — functional height

These square shank tools with back and front H — shank height

clamping are designed for Swiss-type lathes and B — shank width

also can be used on all types of lathe machines.

They are not fitted with coolant channels. OAL — overall length

HBL — head bottom length

HBH — bottom height

CDX — insert overhang

Main Advantages

• Suitable for all types of lathe machines.

• No need to remove a clamping screw for replace insert.

Tools with High Pressure Coolant System for External Threading

These threading square shank tools are designed to carry Basic Dimensions of Threading Tools

SCIR/SCIL inserts and feature coolant channels designed with High Pressure Coolant System

also for the use of high-pressure coolant. The high

pressure coolant channels (JHP) are pinpointed directly OAL

to the cutting edge. Many modern Swiss-type machines LH 5.5 mm (.217”)

are equipped with high pressure pumps and these tools

will enable better performance on these machines. H

These tools are suitable for all types of lathe machines.

UNF 5/16-24 typx3

CWN-CWX

B

50 mm (1.97”)

70 mm (2.76”)

OAL — overall length

LH — head length

Note: high pressure Coolant is described in chapter 2.13 H — shank height

B — shank width

Ensure maximum coolant in the cutting area.

Main Advantages

• Suitable for all types of lathe machines.

• Internal coolant.

• Reduces cutting time.

• Provides longer tool life of cutting edge.

• Enables better chip evacuation.

ISCAR

54