Page 23 - ISCAR_WORLD_2021

P. 23

ANTI-VIBRA TION

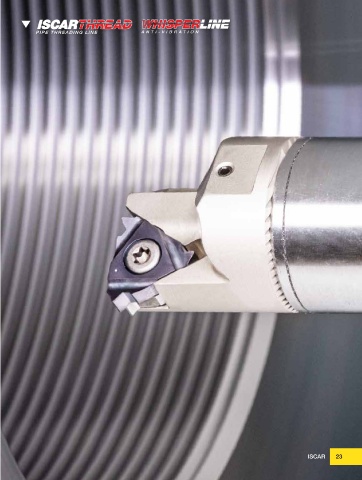

Choosing the Right

Threading Insert

The production of thread connections is a

common application in the metal working

industry. Most metal working industries

produce parts that are characterized by

external or internal threads, from tiny dental

screws to large thread joints for pipelines

associated with the oil and gas industry.

There are a wide variety of thread types produced in

National and International Thread Type Standards.

Thread types differ in shape and dimension, where

each standard defines a specific thread type. In

many cases, a thread type standard characterizes

a specific requirement for an industrial branch or

main field of application. For example, UNJ and

MJ thread type standards are associated with the

Aerospace industry, and NPT and BSPT standards

are associated with the oil and gas industry for

pipelines, pipe connectors, and fittings.

Thread turning applications are one of the most

productive and common methods for producing

threads in rotary workpieces.

A successful thread type turning application depends

on the selection of the right threading tool. There

are simple steps to selecting an indexable threading

tool correctly; first, identify if the thread is external or

internal for which to choose a right- or left-hand tool.

After choosing the feed direction corresponding to the

thread type, the thread designation will be determined

according to the part drawing and application.

TELLIGENTLY

23

ISCAR

22 MACHINING IN DUSTRY 4.0 ISCAR 23