Page 123 - HOLE MAKING CATALOG p185-310

P. 123

Typical Gundrill Applications - USER GUIDE GUNDRILLS

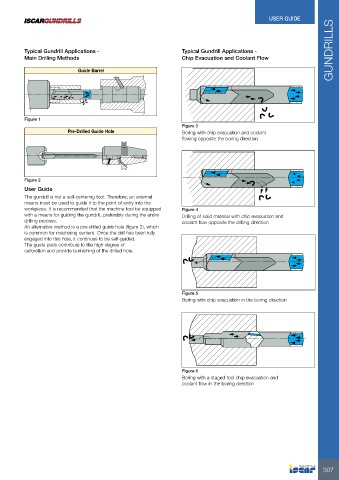

Main Drilling Methods

Typical Gundrill Applications -

Guide Barrel Chip Evacuation and Coolant Flow

Figure 1

Pre-Drilled Guide Hole Figure 3

Boring with chip evacuation and coolant

flowing opposite the boring direction

Figure 2 Figure 4

User Guide Drilling of solid material with chip evacuation and

coolant flow opposite the drilling direction

The gundrill is not a self-centering tool. Therefore, an external

means must be used to guide it to the point of entry into the

workpiece. It is recommended that the machine tool be equipped

with a means for guiding the gundrill, preferably during the entire

drilling process.

An alternative method is a pre-drilled guide hole (figure 2), which

is common for machining centers. Once the drill has been fully

engaged into this hole, it continues to be self-guided.

The guide pads contribute to the high degree of

calibration and provide burnishing of the drilled hole.

Figure 5

Boring with chip evacuation in the boring direction

Figure 6

Boring with a staged tool chip evacuation and

coolant flow in the boring direction

307