Page 41 - TURNING CATALOG p255-458

P. 41

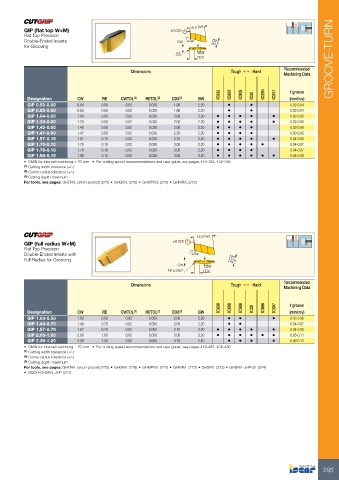

GIP (flat top W<M) ±0.025 15.3 Ref. IC830

Flat Top Precision IC808

Double-Ended Inserts 7° 5 IC908

for Grooving CW IC20

IC20N

RE BW IC807

CDX

GROOVE-TURN

Dimensions Tough 1 Hard Recommended

Machining Data

Designation CW RE CWTOL(1) RETOL(2) CDX(3) BW •• f groove

GIP 0.50-0.00 0.50 0.00 0.02 0.030 1.00 2.20 •• (mm/rev)

GIP 0.80-0.00 0.02-0.04

GIP 1.04-0.00 0.80 0.00 0.02 0.030 1.60 2.20 • 0.02-0.04

GIP 1.20-0.00 1.04 0.00 0.02 0.030 2.00 2.20 • • • • 0.02-0.05

GIP 1.40-0.00 1.20 0.00 0.02 0.030 2.00 2.20 • • • • • 0.03-0.05

GIP 1.47-0.00 1.40 0.00 0.02 0.030 2.00 2.20 • • • • 0.03-0.06

GIP 1.57-0.15 1.47 0.00 0.02 0.030 2.50 2.20 • • • • 0.03-0.06

GIP 1.70-0.10 1.57 0.15 0.02 0.030 2.70 2.20 • • • • • 0.04-0.06

GIP 1.78-0.18 1.70 0.10 0.02 0.030 3.00 2.20 • • • • • 0.04-0.07

GIP 1.96-0.15 1.78 0.18 0.02 0.030 3.00 2.20 • • • • 0.04-0.07

1.96 0.15 0.02 0.030 3.00 2.20 • • • • • • 0.04-0.08

• DMIN for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: GHDR/L (short pocket) (275) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273)

15.3 Ref.

GIP (full radius W<M) ±0.025

Flat Top Precision

Double-Ended Inserts with 7°

Full Radius for Grooving

5

CW BW

RE=CW/2 CDX Tough 1 Hard

Dimensions Recommended

Machining Data

Designation CW RE CWTOL(1) RETOL(2) CDX(3) BW IC830 f groove

IC808

GIP 1.00-0.50 IC908 (mm/rev)

GIP 1.40-0.70 IC20 0.03-0.06

GIP 1.57-0.79 IC806 0.04-0.07

GIP 2.00-1.00 IC807 0.04-0.08

GIP 2.39-1.20 0.05-0.11

1.00 0.50 0.02 0.050 2.00 2.20 •• • 0.06-0.12

•• •

1.40 0.70 0.02 0.050 2.00 2.20 •

1.57 0.79 0.02 0.050 2.70 2.20 • • • • •

2.00 1.00 0.02 0.050 3.00 2.20 • • • • •

2.39 1.20 0.02 0.050 4.70 2.40 •••

• DMIN for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: GHDR/L (short pocket) (275) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374)

• NQCH-GHSR/L-JHP (374)

295