Page 24 - Iscar Article 2_2017

P. 24

inserts? The deceptively simple, new extended

flute tools feature a well-designed structure

resulting in significantly improved dynamic rigidity

and anti-vibration strength. In addition, radial

insert clamping enables the inclusion of a chip

gullet with a generous volume that answers

the requirements of free chip flow when milling

at high metal removal rates (MRR). Also, the

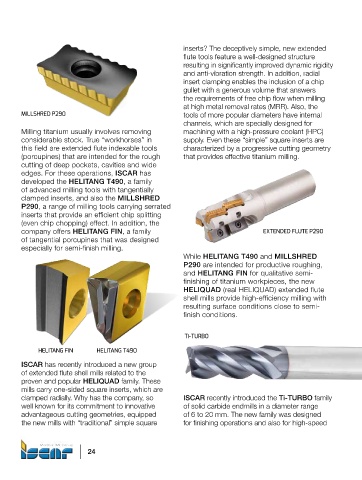

MILLSHRED P290 tools of more popular diameters have internal

channels, which are specially designed for

Milling titanium usually involves removing machining with a high-pressure coolant (HPC)

considerable stock. True “workhorses” in supply. Even these “simple” square inserts are

this field are extended flute indexable tools characterized by a progressive cutting geometry

(porcupines) that are intended for the rough that provides effective titanium milling.

cutting of deep pockets, cavities and wide

edges. For these operations, ISCAR has

developed the HELITANG T490, a family

of advanced milling tools with tangentially

clamped inserts, and also the MILLSHRED

P290, a range of milling tools carrying serrated

inserts that provide an efficient chip splitting

(even chip chopping) effect. In addition, the

company offers HELITANG FIN, a family EXTENDED FLUTE P290

of tangential porcupines that was designed

especially for semi-finish milling.

While HELITANG T490 and MILLSHRED

P290 are intended for productive roughing,

and HELITANG FIN for qualitative semi-

finishing of titanium workpieces, the new

HELIQUAD (real HELIQUAD) extended flute

shell mills provide high-efficiency milling with

resulting surface conditions close to semi-

finish conditions.

Ti-TURBO

HELITANG FIN HELITANG T490

ISCAR has recently introduced a new group

of extended flute shell mills related to the

proven and popular HELIQUAD family. These

mills carry one-sided square inserts, which are

clamped radially. Why has the company, so ISCAR recently introduced the Ti-TURBO family

well known for its commitment to innovative of solid carbide endmills in a diameter range

advantageous cutting geometries, equipped of 6 to 20 mm. The new family was designed

the new mills with “traditional” simple square for finishing operations and also for high-speed

24