Page 42 - FAST_FEED_MILL_Brochure_INCH_2022

P. 42

S W1

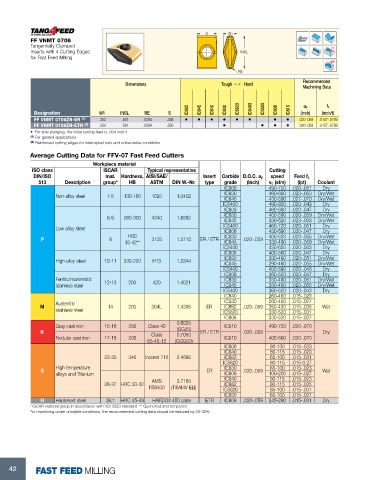

FF VNMT 0706

Tangentially Clamped Rd°

Inserts with 4 Cutting Edges INSL

for Fast Feed Milling

RE

Recommended

Dimensions Tough 1 Hard Machining Data

IC882 IC845 IC840 IC830 IC5820 IC5400 IC5500 IC808 IC810 ap fz

Designation W1 INSL RE S (inch) (inch/t)

FF VNMT 0706ZN-ER (1) .252 .591 .0394 .356 • • • • • • • • .020-.059 .0157-.0709

FF VNMT 0706ZN-ETR (2) .252 .591 .0394 .356 • • • • .020-.059 .0157-.0709

• For side plunging, the initial cutting feed is .004 inch/t

(1) For general applications

(2) Reinforced cutting edges for interrupted cuts and unfavorable conditions

Average Cutting Data for FFV-07 Fast Feed Cutters

Workpiece material

ISO class ISCAR Typical representative Cutting

DIN/ISO mat. Hardness, AISI/SAE/ Insert Carbide D.O.C. ap speed Feed fz

513 Description group* HB ASTM DIN W.-Nr. type grade (inch) vc (sfm) (ipt) Coolant

IC808 490-720 .020-.051 Dry

Non-alloy steel 1-5 130-180 1020 1.0402 IC830 460-660 .023-.063 Dry/Wet

IC845 430-590 .027-.070 Dry/Wet

IC5400 490-820 .020-.043 Dry

IC808 460-660 .020-.047 Dry

6-8 260-300 4340 1.6582 IC830 400-590 .020-.059 Dry/Wet

.023-.063

330-520

Dry/Wet

IC845

IC5400 460-720 .020-.051 Dry

Low alloy steel IC808 430-590 .020-.047 Dry

HRC IC830 400-520 .020-.055 Dry/Wet

P 9 3135 1.5710 ER / ETR .020-.059

35-42** IC845 330-490 .020-.059 Dry/Wet

IC5400 430-620 .020-.043 Dry

IC808 400-560 .020-.047 Dry

High alloy steel 10-11 200-220 H13 1.2344 IC830 330-490 .020-.051 Dry/Wet

Dry/Wet

.020-.055

290-460

IC845

IC5400 400-590 .020-.043 Dry

IC808 360-520 .020-.047 Dry

Ferritic/martensitic IC830 330-490 .020-.051 Dry/Wet

stainless steel 12-13 200 420 1.4021 IC845 330-460 .020-.055 Dry/Wet

IC5400 360-520 .020-.043 Dry

IC840 260-460 .015-.023

Austenitic IC830 260-400 .015-.027

M 14 200 304L 1.4306 ER IC882 .020-.059 260-430 .015-.035 Wet

stainless steel IC5820 330-520 .015-.031

IC808 330-520 .015-.027

0.6025

Gray cast iron 15-16 250 Class 40 IC810 490-720 .020-.070

K Class (GG25) ER / ETR .020-.059 Dry

0.7050

Nodular cast iron 17-18 200 IC810 400-660 .020-.070

65-45-12 (GGG50)

IC808 80-130 .015-.023

IC840 80-115 .015-.020

33-35 340 Inconel 718 2.4668 IC882 65-100 .015-.031

IC5820 80-115 .015-0.27

High temperature IC830 65-100 .015-.023

S ER .020-.059 Wet

alloys and Titanium IC808 100-200 .015-.027

AMS 3.7165 IC840 80-115 .015-.023

36-37 HRC 30-32 IC882 80-115 .015-.035

R56400 (Ti6AI4V ELI) IC5820 65-100 .015-.031

IC830 65-100 .015-.027

H Hardened steel 38.1 HRC 45-49 HARDOX 450 plate ETR IC808 .020-.059 245-290 .015-.031 Dry

* ISCAR material group in accordance with VDI 3323 standard ** Quenched and tempered

For machining under unstable conditions, the recommended cutting data should be reduced by 20-30%

42 FAST FEED MILLING