Page 45 - HOLE_MAKING_CATALOG_INCH_2022_P187-P236

P. 45

USER GUIDE

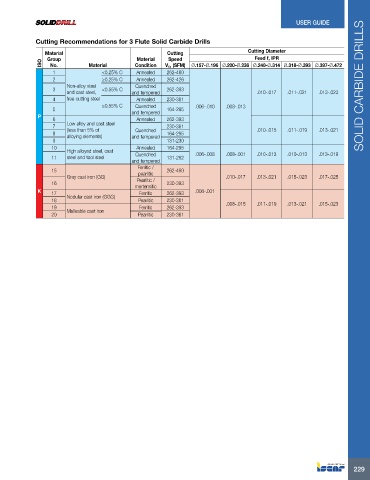

Cutting Recommendations for 3 Flute Solid Carbide Drills

Material Cutting Cutting Diameter

Group Material Speed Feed f, IPR

ISO No. Material Condition Vc, (SFM) Ø.157-Ø.196 Ø.200-Ø.236 Ø.240-Ø.314 Ø.318-Ø.393 Ø.397-Ø.472

1 <0.25% C Annealed 262-460

2 ≥0.25% C Annealed 262-426

Non-alloy steel Quenched SOLID CARBIDE DRILLS

3 and cast steel, <0.55% C and tempered 262-393 .010-.017 .011-.021 .013-.023

4 free cutting steel Annealed 230-361

≥0.55% C Quenched .006-.010 .008-.013

5 and tempered 164-295

P

6 Annealed 262-393

7 Low alloy and cast steel 230-361 .010-.015 .011-.019 .013-.021

(less than 5% of

Quenched

8 alloying elements) and tempered 164-295

9 131-230

10 Annealed 164-295

High alloyed steel, cast .006-.008 .008-.001 .010-.013 .010-.013 .013-.019

11 steel and tool steel Quenched 131-262

and tempered

Ferritic /

15 pearlitic 262-460

Gray cast iron (GG) .010-.017 .013-.021 .015-.023 .017-.025

Pearlitic /

16 martensitic 230-393

K 17 Ferritic 262-393 .008-.001

18 Nodular cast iron (GGG) Pearlitic 230-361 .008-.015 .011-.019 .013-.021 .015-.023

19 Malleable cast iron Ferritic 262-393

20 Pearlitic 230-361

229