Page 47 - HOLE_MAKING_CATALOG_INCH_2022_P187-P236

P. 47

USER GUIDE

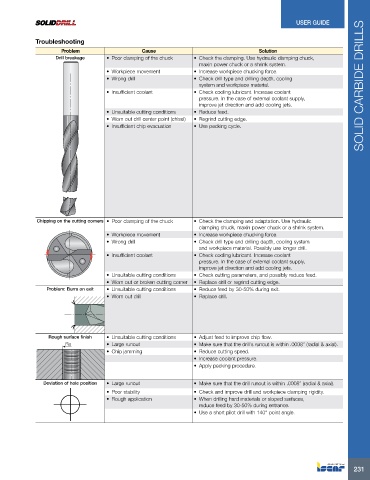

Troubleshooting

Problem Cause Solution

Drill breakage • Poor clamping of the chuck • Check the clamping. Use hydraulic clamping chuck,

maxin power chuck or a shrink system.

• Workpiece movement • Increase workpiece chucking force.

• Wrong drill • Check drill type and drilling depth, cooling

system and workpiece material. SOLID CARBIDE DRILLS

• Insufficient coolant • Check cooling lubricant. Increase coolant

pressure. In the case of external coolant supply,

improve jet direction and add cooling jets.

• Unsuitable cutting conditions • Reduce feed.

• Worn out drill center point (chisel) • Regrind cutting edge.

• Insufficient chip evacuation • Use pecking cycle.

Chipping on the cutting corners • Poor clamping of the chuck • Check the clamping and adaptation. Use hydraulic

clamping chuck, maxin power chuck or a shrink system.

• Workpiece movement • Increase workpiece chucking force.

• Wrong drill • Check drill type and drilling depth, cooling system

and workpiece material. Possibly use longer drill.

• Insufficient coolant • Check cooling lubricant. Increase coolant

pressure. In the case of external coolant supply,

improve jet direction and add cooling jets.

• Unsuitable cutting conditions • Check cutting parameters, and possibly reduce feed.

• Worn out or broken cutting corner • Replace drill or regrind cutting edge.

Problem: Burrs on exit • Unsuitable cutting conditions • Reduce feed by 30-50% during exit.

• Worn out drill • Replace drill.

Rough surface finish • Unsuitable cutting conditions • Adjust feed to improve chip flow.

Ra • Large runout • Make sure that the drill’s runout is within .0008” (radial & axial).

• Chip jamming • Reduce cutting speed.

• Increase coolant pressure.

• Apply pecking procedure.

Deviation of hole position • Large runout • Make sure that the drill runout is within .0008” (radial & axial).

• Poor stability • Check and improve drill and workpiece clamping rigidity.

• Rough application • When drilling hard materials or sloped surfaces,

reduce feed by 30-50% during entrance.

• Use a short pilot drill with 140° point angle.

231