Page 122 - MILLING_CATALOG_INCH_2022_P229-P360

P. 122

DHUB DCONMS

FAST FEED MILLING TOOLS

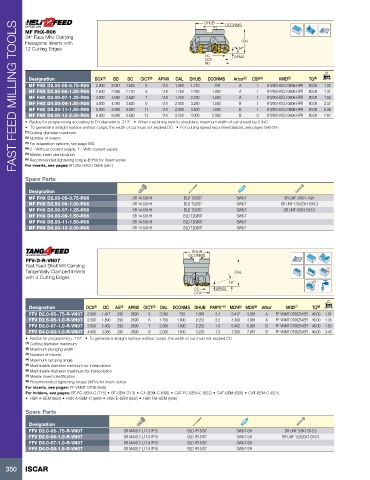

MF FHX-R06

34° Face Mills Carrying

Hexagonal Inserts with OAL

12 Cutting Edges 34°

DC APMX

DCX

BD

Designation DCX (1) BD DC CICT (2) APMX OAL DHUB DCONMS Arbor (3) CSP (4) MIID (5) TQ (6) Lbs

MF FHX D2.00-05-0.75-R06 2.000 2.091 1.625 5 .118 1.500 1.770 .750 A 1 H1200 HXCU 0606-HPR 80.00 1.32

MF FHX D2.50-06-1.00-R06 2.500 2.590 2.120 6 .118 1.750 2.250 1.000 A 1 H1200 HXCU 0606-HPR 80.00 1.31

MF FHX D3.00-07-1.25-R06 3.000 3.090 2.620 7 .118 1.750 2.750 1.250 A 1 H1200 HXCU 0606-HPR 80.00 1.94

MF FHX D4.00-09-1.50-R06 4.000 4.090 3.620 9 .118 2.000 3.250 1.500 B 1 H1200 HXCU 0606-HPR 80.00 3.37

MF FHX D5.00-11-1.50-R06 5.000 5.090 4.620 11 .118 2.000 3.500 1.500 B 1 H1200 HXCU 0606-HPR 80.00 5.36

MF FHX D6.00-13-2.00-R06 6.000 6.090 5.620 13 .118 2.250 4.000 2.000 B 0 H1200 HXCU 0606-HPR 80.00 7.67

• Radius for programming according to D1 diameter is .213" • When machining next to shoulders, maximum width of cut should be 0.3xD

• To generate a straight surface without cusps, the width of cut must not exceed DC • For cutting speed recommendations, see pages 586-591

(1) Cutting diameter maximum

(2) Number of inserts

(3) For adaptation options, see page 592

(4) 0 - Without coolant supply, 1 - With coolant supply

(5) Master insert identification

(6) Recommended tightening torque (lbf*in) for insert screw

For inserts, see pages: H1200 HXCU 0606 (567)

Spare Parts

Designation

MF FHX D2.00-05-0.75-R06 SR 14-591/H BLD T20/S7 SW6-T SR UNF 3/8X1-1421

MF FHX D2.50-06-1.00-R06 SR 14-591/H BLD T20/S7 SW6-T SR UNF 1/2X20X1 B18.3

MF FHX D3.00-07-1.25-R06 SR 14-591/H BLD T20/S7 SW6-T SR UNF 5/8X1 B18.3

MF FHX D4.00-09-1.50-R06 SR 14-591/H BLD T20/M7 SW6-T

MF FHX D5.00-11-1.50-R06 SR 14-591/H BLD T20/M7 SW6-T

MF FHX D6.00-13-2.00-R06 SR 14-591/H BLD T20/M7 SW6-T

DHUB

FFV-D-R-VN07 DCONMS

Fast Feed Shell Mill Carrying

Tangentially Clamped Inserts OAL Rd°

with 4 Cutting Edges

16˚

DC APMX

DCX

Designation DCX (1) DC AE (2) APMX CICT (3) OAL DCONMS DHUB RMPX° (4) MDN (5) MDX (6) Arbor MIID (7) TQ (8) Lbs

FFV D2.0-05-.75-R-VN07 2.000 1.417 .295 .0590 5 2.000 .750 1.850 3.1 3.417 3.961 A FF VNMT 0706ZN-ER 46.00 1.01

FFV D2.5-06-1.0-R-VN07 2.500 1.890 .295 .0590 6 1.750 1.000 2.252 2.2 4.390 4.961 A FF VNMT 0706ZN-ER 46.00 1.35

FFV D3.0-07-1.0-R-VN07 3.000 2.402 .295 .0590 7 2.000 1.000 2.252 1.5 5.402 5.961 B FF VNMT 0706ZN-ER 46.00 1.63

FFV D4.0-08-1.5-R-VN07 4.000 3.386 .295 .0590 8 2.000 1.500 3.228 1.2 7.386 7.961 B FF VNMT 0706ZN-ER 46.00 3.43

• Radius for programming .110" • To generate a straight surface without cusps, the width of cut must not exceed DC

(1) Cutting diameter maximum

(2) Maximum plunging width

(3) Number of inserts

(4) Maximum ramping angle

(5) Machinable diameter minimum for interpolation

(6) Machinable diameter maximum for interpolation

(7) Master insert identification

(8) Recommended tightening torque (lbf*in) for insert screw

For inserts, see pages: FF VNMT 0706 (568)

For holders, see pages: BT-FC-SEM-C (715) • BT-SEM (713) • C#-SEM-C (689) • CAT-FC-SEM-C (622) • CAT-SEM (620) • CAT-SEM-C (621)

• HSK A-SEM (663) • HSK A-SEM-C (669) • HSK E-SEM (662) • HSK FM-SEM (666)

Spare Parts

Designation

FFV D2.0-05-.75-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR UNF 3/8X1 B18.3

FFV D2.5-06-1.0-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR UNF 1/2X20X1 B18.3

FFV D3.0-07-1.0-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH

FFV D4.0-08-1.5-R-VN07 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH

350 ISCAR