Page 118 - MILLING_CATALOG_INCH_2022_P229-P360

P. 118

DHUB

FAST FEED MILLING TOOLS

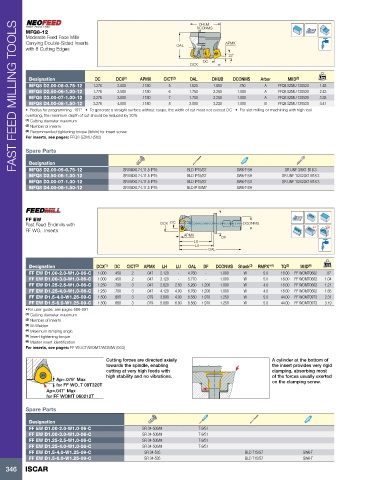

MFQ8-12 DCONMS

Moderate Feed Face Mills

Carrying Double-Sided Inserts OAL APMX

with 8 Cutting Edges

22˚

DC

DCX

Designation DC DCX (1) APMX CICT (2) OAL DHUB DCONMS Arbor MIID (3) Lbs

MFQ8 D2.00-05-0.75-12 1.276 2.000 .1180 5 1.625 1.850 .750 A FFQ8 SZMU 120520 1.48

MFQ8 D2.50-06-1.00-12 1.776 2.500 .1180 6 1.750 2.250 1.000 A FFQ8 SZMU 120520 2.43

MFQ8 D3.00-07-1.00-12 2.276 3.000 .1180 7 1.750 2.250 1.000 A FFQ8 SZMU 120520 3.38

MFQ8 D4.00-08-1.50-12 3.276 4.000 .1180 8 2.000 3.230 1.500 B FFQ8 SZMU 120520 4.41

• Radius for programming .197" • To generate a straight surface without cusps, the width of cut most not exceed DC • For slot milling or machining with high tool

overhang, the maximum depth of cut should be reduced by 30%

(1) Cutting diameter maximum

(2) Number of inserts

(3) Recommended tightening torque (lbfxin) for insert screw

For inserts, see pages: FFQ8 SZMU (562)

Spare Parts

Designation

MFQ8 D2.00-05-0.75-12 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR UNF 3/8X1 B18.3

MFQ8 D2.50-06-1.00-12 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR UNF 1/2X20X1 B18.3

MFQ8 D3.00-07-1.00-12 SR M4X0.7-L11.5 IP15 BLD IP15/S7 SW6-T-SH SR UNF 1/2X20X1 B18.3

MFQ8 D4.00-08-1.50-12 SR M4X0.7-L11.5 IP15 BLD IP15/M7 SW6-T-SH

FF EW

Fast Feed Endmills with DCX DC DCONMS

FF WO.. Inserts Rd°

APMX DF

LU

LH

OAL

Designation DCX (1) DC CICT (2) APMX LH LU OAL DF DCONMS Shank (3) RMPX° (4) TQ (5) MIID (6) Lbs

FF EW D1.00-2.0-W1.0-06-C 1.000 .450 2 .047 2.120 - 4.760 - 1.000 W 5.0 18.00 FF WOMT0602 .87

FF EW D1.00-3.0-W1.0-06-C 1.000 .450 2 .047 3.120 - 5.770 - 1.000 W 5.0 18.00 FF WOMT0602 1.04

FF EW D1.25-2.5-W1.0-06-C 1.250 .700 3 .047 2.620 2.50 5.260 1.200 1.000 W 4.0 18.00 FF WOMT0602 1.21

FF EW D1.25-4.0-W1.0-06-C 1.250 .700 3 .047 4.120 4.00 6.760 1.200 1.000 W 4.0 18.00 FF WOMT0602 1.65

FF EW D1.5-4.0-W1.25-09-C 1.500 .680 3 .079 3.890 4.00 6.580 1.970 1.250 W 5.0 44.00 FF WOMT09T3 2.31

FF EW D1.5-6.0-W1.25-09-C 1.500 .680 3 .079 5.890 6.00 8.580 1.970 1.250 W 5.0 44.00 FF WOMT09T3 3.19

•For user guide, see pages 586-591

(1) Cutting diameter maximum

(2) Number of inserts

(3) W-Weldon

(4) Maximum ramping angle

(5) Insert tightening torque

(6) Master insert identification

For inserts, see pages: FF WOCT/WOMT/WOMW (563)

Cutting forces are directed axially A cylinder at the bottom of

towards the spindle, enabling the insert provides very rigid

cutting at very high feeds with clamping, absorbing most

high stability and no vibrations. of the forces usually exerted

Ap=.079” Max on the clamping screw.

for FF WO_T 09T320T

Ap=.047” Max

for FF WOMT 060212T

Spare Parts

Designation

FF EW D1.00-2.0-W1.0-06-C SR 34-506/M T-9/51

FF EW D1.00-3.0-W1.0-06-C SR 34-506/M T-9/51

FF EW D1.25-2.5-W1.0-06-C SR 34-506/M T-9/51

FF EW D1.25-4.0-W1.0-06-C SR 34-506/M T-9/51

FF EW D1.5-4.0-W1.25-09-C SR 34-535 BLD T15/S7 SW6-T

FF EW D1.5-6.0-W1.25-09-C SR 34-535 BLD T15/S7 SW6-T

346 ISCAR