Page 31 - MILLING_CATALOG_INCH_2022_P229-P360

P. 31

DHUB

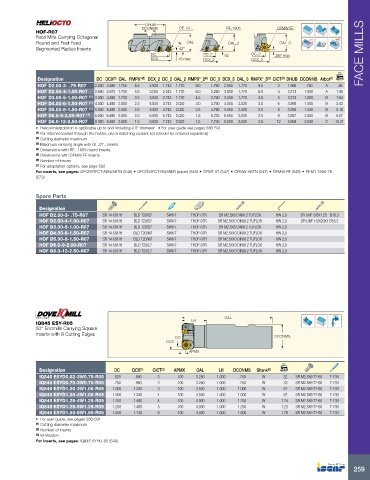

HOF-R07 DCONMS OF.. 07.. RF..1905 OFMW FF

Face Mills Carrying Octagonal

Round and Fast Feed OAL OAL_2 OAL_3 Rd°

Segmented Radius Inserts 42°

DC DC_2 .39 DC_3 .087 max FACE MILLS

DCX .18 max DCX_2 DCX_3

(6)

Designation DC DCX (2) OAL RMPX° (3) DCX_2 DC_2 OAL_2 RMPX°_2 (4) DC_3 DCX_3 OAL_3 RMPX°_3 (5) CICT DHUB DCONMS Arbor (7) Lbs

HOF D2.00-3- .75-R07 2.000 2.490 1.750 6.5 2.520 1.743 1.770 9.0 1.790 2.550 1.770 9.0 3 1.890 .750 A .88

HOF D2.50-4-1.00-R07 2.500 2.972 1.750 5.0 3.020 2.243 1.770 6.0 2.290 3.050 1.770 6.0 4 2.213 1.000 A 1.36

HOF D3.00-5-1.00-R07 (1) 3.000 3.490 1.750 3.5 3.520 2.743 1.770 4.5 2.790 3.550 1.770 4.5 5 2.213 1.000 B 1.64

HOF D4.00-6-1.50-R07 (1) 4.000 4.490 2.000 2.5 4.520 3.743 2.020 3.0 3.790 4.550 2.020 3.0 6 3.268 1.500 B 3.43

HOF D5.00-8-1.50-R07 (1) 5.000 5.490 2.000 2.5 5.520 4.743 2.020 2.5 4.790 5.550 2.020 2.5 8 3.268 1.500 B 5.18

HOF D6.0-9-2.00-R07 (1) 6.000 6.490 2.000 2.0 6.520 5.743 2.020 1.8 5.730 6.550 2.020 2.5 9 3.937 2.000 B 6.57

HOF D8.0-12-2.50-R07 8.000 8.490 2.500 1.5 8.520 7.743 2.020 1.5 7.730 8.550 2.020 2.5 12 5.906 2.500 C 15.21

• Helical interpolation is applicable up to and including 4.0" diameter • For user guide see pages 586-591

(1) For internal coolant through the holder, use a matching coolant set (should be ordered separately)

(2) Cutting diameter maximum

(3) Maximum ramping angle with OF..07.. inserts

(4) Dimensions with RF.. 1905 round inserts.

(5) Dimensions with OFMW FF inserts.

(6) Number of inserts

(7) For adaptation options, see page 592

For inserts, see pages: OFCR/OFCT-AEN/AETN (548) • OFCR/OFCT-RW/AER (wiper) (548) • OFMT 07 (547) • OFMW-AETN (547) • OFMW-FF (549) • RFMT 1905-76

(573)

Spare Parts

Designation

HOF D2.00-3- .75-R07 SR 14-591/H BLD T20/S7 SW6-T THOF-07R SR M2.5X8 DIN912 TUFLOK HW 2.0 SR UNF 3/8X1.25 B18.3

HOF D2.50-4-1.00-R07 SR 14-591/H BLD T20/S7 SW6-T THOF-07R SR M2.5X10 DIN912 TUFLOK HW 2.0 SR UNF 1/2X20X1 B18.3

HOF D3.00-5-1.00-R07 SR 14-591/H BLD T20/S7 SW6-T THOF-07R SR M2.5X8 DIN912 TUFLOK HW 2.0

HOF D4.00-6-1.50-R07 SR 14-591/H BLD T20/M7 SW6-T THOF-07R SR M2.5X10 DIN912 TUFLOK HW 2.0

HOF D5.00-8-1.50-R07 SR 14-591/H BLD T20/M7 SW6-T THOF-07R SR M2.5X10 DIN912 TUFLOK HW 2.0

HOF D6.0-9-2.00-R07 SR 14-591/H BLD T20/L7 SW6-T THOF-07R SR M2.5X10 DIN912 TUFLOK HW 2.0

HOF D8.0-12-2.50-R07 SR 14-591/H BLD T20/L7 SW6-T THOF-07R SR M2.5X10 DIN912 TUFLOK HW 2.0

OAL

IQ845 ESY-R05 LH

50° Endmills Carrying Square

Inserts with 8 Cutting Edges

DC DCONMS

DCX

APMX

Designation DC DCX (1) CICT (2) APMX OAL LH DCONMS Shank (3) Lbs

IQ845 ESYD0.62-3W0.75-R05 .620 .840 3 .100 3.250 1.000 .750 W .32 SR M2.5X6-T7-60 T-7/51

IQ845 ESYD0.75-3W0.75-R05 .750 .960 3 .100 3.250 1.000 .750 W .33 SR M2.5X6-T7-60 T-7/51

IQ845 ESYD1.00-3W1.00-R05 1.000 1.220 3 .100 3.500 1.000 1.000 W .67 SR M2.5X6-T7-60 T-7/51

IQ845 ESYD1.00-4W1.00-R05 1.000 1.220 4 .100 3.500 1.000 1.000 W .67 SR M2.5X6-T7-60 T-7/51

IQ845 ESYD1.25-4W1.25-R05 1.250 1.480 4 .100 4.000 1.000 1.250 W 1.24 SR M2.5X6-T7-60 T-7/51

IQ845 ESYD1.25-5W1.25-R05 1.250 1.480 5 .100 4.000 1.000 1.250 W 1.23 SR M2.5X6-T7-60 T-7/51

IQ845 ESYD1.50-6W1.50-R05 1.500 1.730 6 .100 4.000 1.000 1.500 W 1.78 SR M2.5X6-T7-60 T-7/51

• For user guide, see pages 586-591

(1) Cutting diameter maximum

(2) Number of inserts

(3) W-Weldon

For inserts, see pages: IQ845 SYHU-05 (540)

259