Page 70 - MILLING_CATALOG_INCH_2022_P229-P360

P. 70

USER GUIDE

PLUNGING CUTTERS

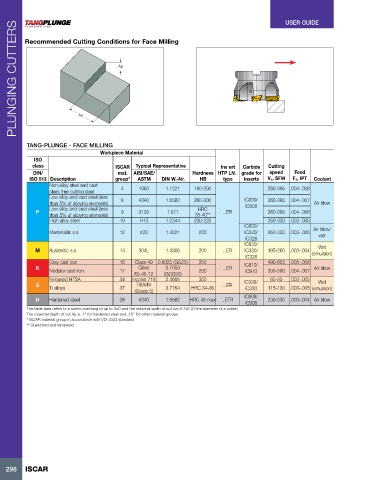

Recommended Cutting Conditions for Face Milling

Ap

Ae

TANG-PLUNGE - FACE MILLING

Workpiece Material

ISO

class ISCAR Typical Representative Ins ert Carbide Cutting

DIN/ mat. AISI/SAE/ Hardness HTP LN… grade for speed Feed

ISO 513 Description group* ASTM DIN W.-Nr. HB type inserts Vc, SFM Fz, IPT Coolant

Non-alloy steel and cast

steel, free cutting steel 4 1060 1.1221 180-200 260-395 .004-.008

Low alloy and cast steel (less 8 4340 1.6582 260-300 IC830/ 260-395 .004-.007

than 5% of alloying elements) Air blow

Low alloy and cast steel (less HRC IC928

P 9 3135 1.571 …ER 260-395 .004-.006

than 5% of alloying elements) 35-40**

High alloy steel 10 H13 1.2344 200-220 260-330 .003-.006

IC830/

Martensitic s.s. 12 420 1.4021 200 IC330/ 260-330 .003-.006 Air blow/

wet

IC328

IC830/

Wet

M Austenitic s.s. 14 304L 1.4306 200 …ER IC330/ 195-260 .003-.004 (emulsion)

IC328

Grey cast iron 16 Class 40 0.6025 (GG25) 250 490-655 .005-.008

K Class 0.7050 …ER IC810/ Air blow

Nodular cast iron 17 200 IC910 330-590 .004-.007

65-45-12 (GGG50)

Ni-based HTSA 34 Inconel 718 2.4668 350 IC328/ 65-80 .003-.005 Wet

S Ti alloys 37 Ti6Al4V 3.7164 HRC 34-36 …ER 115-130 .003-.005

(Grade 5) IC330 (emulsion)

IC808/

H Hardened steel 38 4340 1.6582 HRC 45 max …ETR 230-330 .003-.004 Air blow

IC908

The table data refers to a cutter overhang of up to 4xD and the maximal width of cut Ae=0.7xD (D-the diameter of a cutter)

The maximal depth of cut Ap is .1” for hardened steel and .12” for other material groups

* ISCAR material group in accordance with VDI 3323 standard

** Quenched and tempered

298 ISCAR