Page 65 - MILLING_CATALOG_INCH_2022_P229-P360

P. 65

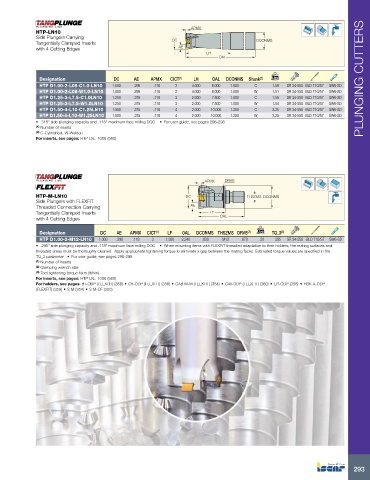

HTP-LN10 APMX

Side Plungers Carrying DC

Tangentially Clamped Inserts DCONMS

with 4 Cutting Edges AE

LH

OAL

Designation DC AE APMX CICT (1) LH OAL DCONMS Shank (2) Lbs PLUNGING CUTTERS

HTP D1.00-2-L08-C1.0-LN10 1.000 .295 .118 2 4.000 8.000 1.000 C 1.59 SR 34-550 BLD T10/S7 SW6-SD

HTP D1.00-2-L08-W1.0-LN10 1.000 .295 .118 2 4.000 8.000 1.000 W 1.51 SR 34-550 BLD T10/S7 SW6-SD

HTP D1.25-3-L7.5-C1.0LN10 1.250 .315 .118 3 2.000 7.500 1.000 C 1.55 SR 34-550 BLD T10/S7 SW6-SD

HTP D1.25-3-L7.5-W1.0LN10 1.250 .315 .118 3 2.000 7.500 1.000 W 1.54 SR 34-550 BLD T10/S7 SW6-SD

HTP D1.50-4-L10-C1.25LN10 1.500 .315 .118 4 2.000 10.000 1.250 C 3.25 SR 34-550 BLD T10/S7 SW6-SD

HTP D1.50-4-L10-W1.25LN10 1.500 .315 .118 4 2.000 10.000 1.250 W 3.25 SR 34-550 BLD T10/S7 SW6-SD

• .315" side plunging capacity and .118" maximum face milling DOC • For user guide, see pages 296-298

(1) Number of inserts

(2) C-Cylindrical, W-Weldon

For inserts, see pages: HTP LN.. 1006 (580)

APMX DRVS

HTP-M-LN10 DC THSZMS DCONMS

Side Plungers with FLEXFIT

Threaded Connection Carrying AE

Tangentially Clamped Inserts LF

with 4 Cutting Edges OAL

Designation DC AE APMX CICT (1) LF OAL DCONMS THSZMS DRVS (2) Lbs TQ_3 (3)

HTP D1.00-2-M12-LN10 1.000 .295 .118 2 1.380 2.240 .830 M12 .670 .20 295 SR 34-550 BLD T10/S7 SW6-SD

• .295" side plunging capacity and .118" maximum face milling DOC • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and

threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the

TQ_3 parameter • For user guide, see pages 296-298

(1) Number of inserts

(2) Clamping wrench size

(3) Tool tightening torque Nxm (lbfxin)

For inserts, see pages: HTP LN.. 1006 (580)

For holders, see pages: BT-ODP (FLEXFIT) (356) • C#-ODP (FLEXFIT) (356) • CAB M-M (FLEXFIT) (354) • CAT-ODP (FLEXFIT) (360) • ER-ODP (358) • HSK A-ODP

(FLEXFIT) (359) • S M (354) • S M-CF (355)

293