Page 61 - MILLING_CATALOG_INCH_2022_P93-P228

P. 61

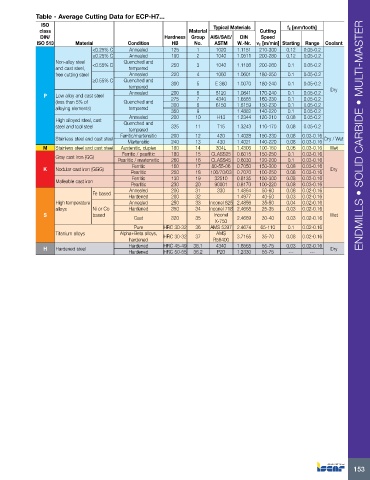

Table - Average Cutting Data for ECP-H7...

ISO Typical Materials fz [mm/tooth]

class Material Cutting

DIN/ Hardness Group AISI/SAE/ DIN Speed

ISO 513 Material Condition HB No. ASTM W.-Nr. vc [m/min] Starting Range Coolant

<0.25% C Annealed 125 1 1020 1.1151 210-300 0.12 0.05-0.2

≥0.25% C Annealed 190 2 1040 1.0511 200-280 0.12 0.05-0.2

Non-alloy steel <0.55% C Quenched and 250 3 1040 1.1186 200-260 0.1 0.05-0.2

and cast steel, tempered

free cutting steel Annealed 220 4 1060 1.0601 180-250 0.1 0.05-0.2

≥0.55% C Quenched and 300 5 E 360 1.0070 180-240 0.1 0.05-0.2

tempered Dry

P Low alloy and cast steel Annealed 200 6 5120 1.0841 170-240 0.1 0.05-0.2

(less than 5% of Quenched and 275 7 8 4340 1.6565 160-230 0.1 0.05-0.2

1.8159

6150

300

0.05-0.2

150-230

0.1

alloying elements) tempered 350 9 1.4882 140-220 0.1 0.05-0.2

Annealed 200 10 H13 1.2344 120-210 0.08 0.05-0.2

High alloyed steel, cast Quenched and

steel and tool steel 325 11 T15 1.3243 110-170 0.08 0.05-0.2

tempered

Ferritic/martensitic 200 12 420 1.4028 150-230 0.08 0.03-0.16 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

Stainless steel and cast steel Dry / Wet

Martensitic 240 13 430 1.4021 140-220 0.08 0.03-0.16

M Stainless steel and cast steel Austenitic, duplex 180 14 304L 1.4306 100-160 0.06 0.03-0.16 Wet

Ferritic / pearlitic 180 15 CLASS25 0.6015 150-250 0.1 0.03-0.16

Gray cast iron (GG)

Pearlitic / martensitic 260 16 CLASS45 0.6030 120-200 0.1 0.03-0.16

K Nodular cast iron (GGG) Ferritic 160 17 80-55-06 0.7050 150-300 0.08 0.03-0.16 Dry

Pearlitic 250 18 100/70/03 0.7070 100-250 0.08 0.03-0.16

Ferritic 130 19 32510 0.8135 150-300 0.08 0.03-0.16

Malleable cast iron

Pearlitic 230 20 90001 0.8170 100-220 0.08 0.03-0.16

Annealed 200 31 330 1.4864 50-60 0.08 0.02-0.16

Fe based

Hardened 280 32 1.4977 40-50 0.03 0.02-0.16

High temperature Annealed 250 33 Inconel 625 2.4856 35-50 0.04 0.02-0.16

alloys Ni or Co Hardened 350 34 Inconel 718 2.4668 25-35 0.03 0.02-0.16

S based Inconel Wet

Cast 320 35 2.4669 30-40 0.03 0.02-0.16

X-750

Pure HRC 30-32 36 AMS 5397 2.4674 65-110 0.1 0.02-0.16

Titanium alloys Alpha+Beta alloys, HRC 30-32 37 AMS 3.7165 35-70 0.08 0.02-0.16

hardened R56400

Hardened HRC 45-49 38.1 4340 1.6565 55-75 0.03 0.02-0.16

H Hardened steel Hardened HRC 50-55 38.2 P20 1.2330 55-75 --- --- Dry

153