Page 62 - MILLING_CATALOG_INCH_2022_P93-P228

P. 62

Rd°

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

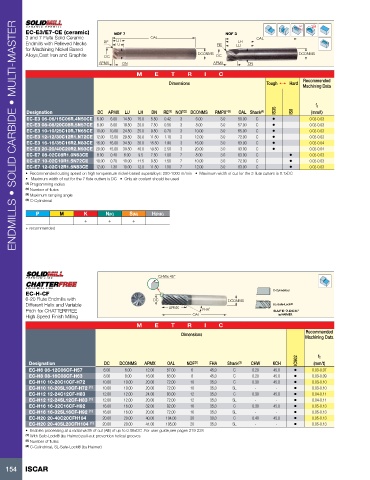

EC-E3/E7-CE (ceramic) NOF 7 NOF 3

3 and 7 Flute Solid Ceramic LH OAL OAL

Endmills with Relieved Necks RE LU RE LU LH

for Machining Nickel Based

Alloys,Cast Iron and Graphite DC DCONMS DC DCONMS

APMX DN APMX DN

M E T R I C

Recommended

Dimensions Tough 1 Hard

Machining Data

fz

Designation DC APMX LU LH DN RE (1) NOF (2) DCONMS RMPX° (3) OAL Shank (4) IS35 IS6 (mm/t)

EC-E3 06-06/15C06R.4N50CE 6.00 6.00 14.50 15.0 5.50 0.42 3 6.00 3.0 50.00 C • 0.02-0.03

EC-E3 08-08/20C08R.5N57CE 8.00 8.00 19.50 20.0 7.50 0.56 3 8.00 3.0 57.00 C • 0.02-0.03

EC-E3 10-10/25C10R.7N65CE 10.00 10.00 24.50 25.0 9.50 0.70 3 10.00 3.0 65.00 C • 0.02-0.03

EC-E3 12-12/30C12R1.N72CE 12.00 12.00 29.50 30.0 11.50 1.10 3 12.00 3.0 72.00 C • 0.02-0.03

EC-E3 16-16/35C16R2.N83CE 16.00 16.00 34.50 35.0 15.50 1.90 3 16.00 3.0 83.00 C • 0.02-0.04

EC-E3 20-20/40C20R2.N93CE 20.00 15.00 39.50 40.0 19.50 2.50 3 20.00 3.0 93.00 C • 0.02-0.04

EC-E7 08-02C08R1.0N63CE 8.00 0.40 8.00 9.5 7.50 1.00 7 8.00 3.0 63.00 C • 0.02-0.03

EC-E7 10-02C10R1.5N72CE 10.00 0.70 10.00 11.5 9.50 1.50 7 10.00 3.0 72.00 C • 0.02-0.03

EC-E7 12-02C12R1.5N83CE 12.00 1.30 10.00 12.0 11.50 1.50 7 12.00 3.0 83.00 C • 0.02-0.03

• Recommended cutting speed on high temperature nickel-based superalloys: 250-1000 m/min • Maximum width of cut for the 3 flute cutters is 0.1xDC

• Maximum width of cut for the 7 flute cutters is DC • Only air coolant should be used

(1) Programming radius

(2) Number of flutes

(3) Maximum ramping angle

(4) C-Cylindrical

P M K N(K) S(M) H(P/K)

+ + +

+ recommended

CHWx 45°

EC-H-CF C-Cylindrical

6-20 Flute Endmills with DC DCONMS

Different Helix and Variable APMX SL-Safe-Lock®

Pitch for CHATTERFREE FHA˚

High Speed Finish Milling OAL

M E T R I C

Recommended

Dimensions Machining Data

IC902 fz

Designation DC DCONMS APMX OAL NOF (2) FHA Shank (3) CHW KCH (mm/t)

EC-H6 06-12C06CF-H57 6.00 6.00 12.00 57.00 6 45.0 C 0.20 45.0 • 0.03-0.07

EC-H8 08-16C08CF-H63 8.00 8.00 16.00 63.00 8 45.0 C 0.20 45.0 • 0.03-0.09

EC-H10 10-20C10CF-H72 10.00 10.00 20.00 72.00 10 35.0 C 0.30 45.0 • 0.03-0.10

EC-H10 10-20SL10CF-H72 (1) 10.00 10.00 20.00 72.00 10 35.0 SL - - • 0.03-0.10

EC-H12 12-24C12CF-H83 12.00 12.00 24.00 83.00 12 35.0 C 0.30 45.0 • 0.04-0.11

EC-H12 12-24SL12CF-H83 (1) 12.00 12.00 20.00 72.00 12 35.0 SL - - • 0.04-0.11

EC-H16 16-32C16CF-H92 16.00 16.00 32.00 92.00 16 35.0 C 0.30 45.0 • 0.05-0.13

EC-H16 16-32SL16CF-H92 (1) 16.00 16.00 20.00 72.00 16 35.0 SL - - • 0.05-0.13

EC-H20 20-40C20CFH104 20.00 20.00 40.00 104.00 20 30.0 C 0.40 45.0 • 0.05-0.13

EC-H20 20-40SL20CFH104 (1) 20.00 20.00 41.00 105.00 20 35.0 SL - - • 0.05-0.13

• Enables processing at a radial width of cut (AE) of up to 0.06xDC .For user guide,see pages 219-228

(1) With Safe-Lock® (by Haimer) pull-out prevention helical grooves

(2) Number of flutes

(3) C-Cylindrical, SL-Safe-Lock® (by Haimer)

154 ISCAR