Page 54 - NEW_PRODUCT_CATALOG_2022

P. 54

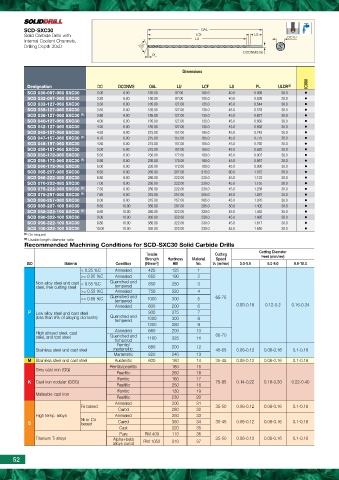

SCD-SXC30 OAL

Solid Carbide Drills with LCF LS DC h7

Internal Coolant Channels, LU

Drilling Depth 30xD 135

DCONMS h6

PL

Dimensions

IC908

Designation DC DCONMS OAL LU LCF LS PL ULDR (2)

SCD 030-097-060 SXC30 3.00 6.00 150.00 97.00 105.0 40.0 0.495 30.0 •

SCD 032-097-060 SXC30 3.20 6.00 150.00 97.00 105.0 40.0 0.528 30.0 •

SCD 033-127-060 SXC30 3.30 6.00 185.00 127.00 135.0 45.0 0.544 30.0 •

SCD 035-127-060 SXC30 3.50 6.00 185.00 127.00 135.0 45.0 0.578 30.0 •

SCD 038-127-060 SXC30 (1) 3.80 6.00 185.00 127.00 135.0 45.0 0.627 30.0 •

SCD 040-127-060 SXC30 4.00 6.00 185.00 127.00 135.0 45.0 0.660 30.0 •

SCD 042-127-060 SXC30 4.20 6.00 185.00 127.00 135.0 45.0 0.693 30.0 •

SCD 045-157-060 SXC30 4.50 6.00 215.00 157.00 165.0 45.0 0.743 30.0 •

SCD 047-157-060 SXC30 (1) 4.70 6.00 215.00 157.00 165.0 45.0 0.775 30.0 •

SCD 048-157-060 SXC30 4.80 6.00 215.00 157.00 165.0 45.0 0.792 30.0 •

SCD 050-157-060 SXC30 5.00 6.00 215.00 157.00 165.0 45.0 0.825 30.0 •

SCD 055-172-060 SXC30 5.50 6.00 230.00 172.00 180.0 45.0 0.907 30.0 •

SCD 058-172-060 SXC30 (1) 5.80 6.00 230.00 172.00 180.0 45.0 0.957 30.0 •

SCD 060-172-060 SXC30 6.00 6.00 230.00 172.00 180.0 45.0 0.990 30.0 •

SCD 065-207-080 SXC30 6.50 8.00 280.00 207.00 215.0 60.0 1.072 30.0 •

SCD 068-222-080 SXC30 6.80 8.00 280.00 222.00 230.0 45.0 1.122 30.0 •

SCD 070-222-080 SXC30 7.00 8.00 280.00 222.00 230.0 45.0 1.155 30.0 •

SCD 075-222-080 SXC30 (1) 7.50 8.00 280.00 222.00 230.0 45.0 1.238 30.0 •

SCD 078-257-080 SXC30 (1) 7.80 8.00 315.00 257.00 265.0 45.0 1.287 30.0 •

SCD 080-257-080 SXC30 8.00 8.00 315.00 257.00 265.0 45.0 1.320 30.0 •

SCD 085-287-100 SXC30 8.50 10.00 350.00 287.00 295.0 50.0 1.402 30.0 •

SCD 088-322-100 SXC30 (1) 8.80 10.00 380.00 322.00 330.0 45.0 1.452 30.0 •

SCD 090-322-100 SXC30 9.00 10.00 380.00 322.00 330.0 45.0 1.485 30.0 •

SCD 098-322-100 SXC30 9.80 10.00 380.00 322.00 330.0 45.0 1.617 30.0 •

SCD 100-322-100 SXC30 10.00 10.00 380.00 322.00 330.0 45.0 1.650 30.0 •

(1) On request

(2) Usable length diameter ratio

Recommended Machining Conditions for SCD-SXC30 Solid Carbide Drills

Cutting Diameter

Tensile Cutting

Strength Hardness Material Speed Feed (mm/rev)

ISO Material Condition [N/mm ] 2 HB No. Vc (m/min) 3.0-5.0 5.0-8.0 8.0-10.0

< 0.25 %C Annealed 420 125 1

>= 0.25 %C Annealed 650 190 2

Non-alloy steel and cast < 0.55 %C Quenched and 850 250 3

steel, free cutting steel tempered

>= 0.55 %C Annealed 750 220 4

>= 0.55 %C Quenched and 1000 300 5 65-75

tempered

Annealed 600 200 6 0.08-0.16 0.12-0.2 0.16-0.24

P Low alloy steel and cast steel 930 275 7

(less than 5% of alloying elements) Quenched and 1000 300 8

tempered

1200 350 9

Annealed 680 200 10

High alloyed steel, cast

steel, and tool steel Quenched and 1100 325 11 60-70

tempered

Ferritic/ 680 200 12

Stainless steel and cast steel martensitic. 45-55 0.06-0.12 0.08-0.16 0.1-0.18

Martensitic 820 240 13

M Stainless steel and cast steel Austenitic 600 180 14 35-45 0.06-0.12 0.08-0.16 0.1-0.18

Ferritic/pearlitic 180 15

Grey cast iron (GG)

Pearlitic 260 16

Ferritic 160 17

K Cast iron nodular (GGG) 75-85 0.14-0.22 0.18-0.30 0.22-0.40

Pearlitic 250 18

Ferritic 130 19

Malleable cast iron

Pearlitic 230 20

Annealed 200 31

Fe based 35-50 0.06-0.12 0.08-0.16 0.1-0.18

Cured 280 32

High temp. alloys Annealed 250 33

Ni or Co

S based Cured 350 34 30-45 0.06-0.12 0.08-0.16 0.1-0.18

Cast 320 35

Pure RM 400 110 36

Titanium Ti alloys Alpha+beta 35-50 0.06-0.12 0.08-0.16 0.1-0.18

alloys cured RM 1050 310 37

52