Page 56 - NEW_PRODUCT_CATALOG_2022

P. 56

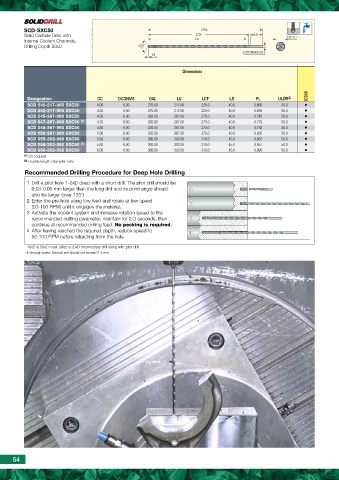

SCD-SXC50 OAL

Solid Carbide Drills with LCF LS DC h7

Internal Coolant Channels, LU

Drilling Depth 50xD 135

DCONMS h6

PL

Dimensions

IC908

Designation DC DCONMS OAL LU LCF LS PL ULDR (2)

SCD 040-217-060 SXC50 4.00 6.00 270.00 217.00 225.0 40.0 0.660 50.0 •

SCD 042-217-060 SXC50 4.20 6.00 270.00 217.00 225.0 40.0 0.693 50.0 •

SCD 045-267-060 SXC50 4.50 6.00 320.00 267.00 275.0 40.0 0.743 50.0 •

SCD 047-267-060 SXC50 (1) 4.70 6.00 320.00 267.00 275.0 40.0 0.775 50.0 •

SCD 048-267-060 SXC50 4.80 6.00 320.00 267.00 275.0 40.0 0.792 50.0 •

SCD 050-267-060 SXC50 5.00 6.00 320.00 267.00 275.0 40.0 0.825 50.0 •

SCD 055-302-060 SXC50 5.50 6.00 360.00 302.00 310.0 45.0 0.907 50.0 •

SCD 058-302-060 SXC50 (1) 5.80 6.00 360.00 302.00 310.0 45.0 0.957 50.0 •

SCD 060-302-060 SXC50 6.00 6.00 360.00 302.00 310.0 45.0 0.990 50.0 •

(1) On request

(2) Usable length diameter ratio

Recommended Drilling Procedure for Deep Hole Drilling

1 Drill a pilot hole 1-2xD deep with a short drill. The pilot drill should be

0.03-0.05 mm larger than the long drill and its point angle should 1

also be larger (over 135°).

2 Enter the pre-hole using low feed and rotate at low speed 2

(50-100 RPM) until it engages the material.

3 Activate the coolant system and increase rotation speed to the

recommended cutting parameter, maintain for 2-3 seconds, then 3

continue at recommended drilling feed. No pecking is required.

4 After having reached the required depth, reduce speed to 4

50-100 RPM before retracting from the hole.

- 40xD & 50xD must utilize a 20xD intermediary drill along with pilot drill.

- In through holes, the tool exit should not exceed 2-3 mm.

54