Page 105 - Turning_catalog_INCH_2022_45_P261-508

P. 105

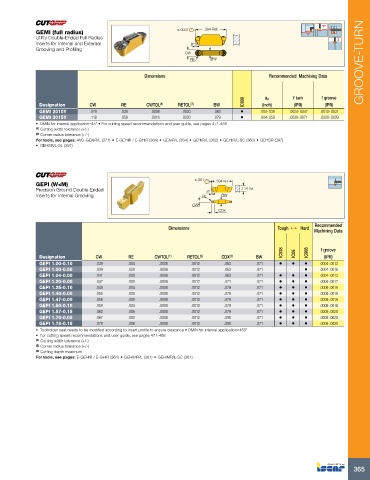

GEMI (full radius) ±.0031 .394 Ref.

Utility Double-Ended Full Radius

Inserts for Internal and External 8°

Grooving and Profiling

CW

RE BW GROOVE-TURN

Dimensions Recommended Machining Data

IC808 ap f turn f groove

Designation CW RE CWTOL (1) RETOL (2) BW (inch) (IPR) (IPR)

GEMI 2010Y .079 .039 .0008 .0020 .063 • .004-.039 .0024-.0047 .0012-.0031

GEMI 3015Y .118 .059 .0016 .0020 .079 • .004-.059 .0039-.0071 .0020-.0039

• DMIN for internal application=45" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: AVC-GEAIR/L (371) • E-GEHIR / E-GHIR (364) • GEAIR/L (364) • GEHIR/L (362) • GEHIR/L-SC (363) • GEHSR (397)

• GEHSR/L-SL (397)

GEPI (W<M) ±.001 .394 Ref.

Precision Ground Double-Ended 8° .114 Ref.

Inserts for Internal Grooving RE BW

CW

CDX

Dimensions Tough 1 Hard Recommended

Machining Data

IC528 IC08 IC908 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) BW (IPR)

GEPI 1.00-0.10 .039 .004 .0008 .0012 .063 .071 • • • .0004-.0012

GEPI 1.00-0.50 .039 .020 .0008 .0012 .063 .071 • .0004-.0016

GEPI 1.04-0.00 .041 .000 .0008 .0012 .063 .071 • • • .0004-.0012

GEPI 1.20-0.00 .047 .000 .0008 .0012 .071 .071 • • • .0004-.0012

GEPI 1.25-0.10 .049 .004 .0008 .0012 .079 .071 • • • .0008-.0016

GEPI 1.40-0.00 .055 .000 .0008 .0012 .079 .071 • • • .0008-.0016

GEPI 1.47-0.00 .058 .000 .0008 .0012 .079 .071 • • • .0008-.0016

GEPI 1.50-0.10 .059 .004 .0008 .0012 .079 .071 • • • .0008-.0016

GEPI 1.57-0.15 .062 .006 .0008 .0012 .079 .071 • • • .0008-.0020

GEPI 1.70-0.05 .067 .002 .0008 .0012 .098 .071 • • • .0008-.0020

GEPI 1.78-0.15 .070 .006 .0008 .0012 .098 .071 • • • .0008-.0020

• Toolholder seat needs to be modified according to insert profile to ensure clearance • DMIN for internal application=453"

• For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: E-GEHIR / E-GHIR (364) • GEHIMR/L (361) • GEHIMR/L-SC (361)

365