Page 109 - Turning_catalog_INCH_2022_45_P261-508

P. 109

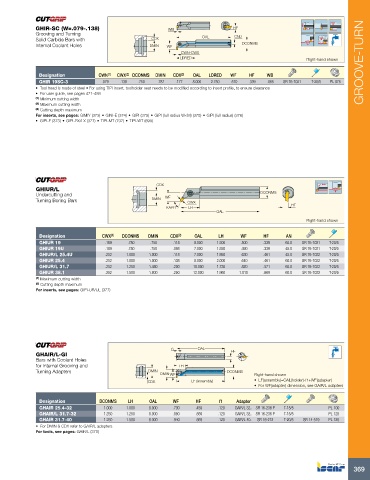

GHIR-SC (W=.079-.138) WB HF

Grooving and Turning CND

Solid Carbide Bars with CDX OAL

Internal Coolant Holes DMIN WF DCONMS

CWN-CWX

LDRED Right-hand shown GROOVE-TURN

Designation CWN (1) CWX (2) DCONMS DMIN CDX (3) OAL LDRED WF HF WB

GHIR 19SC-3 .079 .138 .750 .787 .177 8.000 2.750 .570 .339 .065 SR 76-1021 T-20/5 PL 075

• Tool head is made of steel • For using TIPI insert, toolholder seat needs to be modified according to insert profile, to ensure clearance

• For user guide, see pages 471-488

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GIMIY (373) • GINI-E (374) • GIPI (375) • GIPI (full radius W<M) (375) • GIPI (full radius) (376)

• GIPI-E (373) • GIPI-RX/LX (377) • TIPI-MT (707) • TIPI-WT (699)

GHIUR/L CDX

Undercutting and WF DCONMS

Turning Boring Bars DMIN CWX

KAPR LH HF

OAL

Right-hand shown

Designation CWX (1) DCONMS DMIN CDX (2) OAL LH WF HF AN

GHIUR 19 .189 .750 .750 .118 8.000 1.500 .500 .339 60.0 SR 76-1021 T-20/5

GHIUR 19U .189 .750 .750 .098 7.000 1.550 .490 .339 45.0 SR 76-1021 T-20/5

GHIUR/L 25.4U .252 1.000 1.000 .118 7.000 1.950 .630 .461 45.0 SR 76-1022 T-20/5

GHIUR 25.4 .252 1.000 1.000 .138 8.000 2.000 .640 .461 60.0 SR 76-1022 T-20/5

GHIUR/L 31.7 .252 1.250 1.480 .200 10.000 1.730 .820 .571 60.0 SR 76-1022 T-20/5

GHIUR 38.1 .252 1.500 1.800 .250 12.000 1.960 1.010 .669 60.0 SR 76-1022 T-20/5

(1) Maximum cutting width

(2) Cutting depth maximum

For inserts, see pages: GIPI-UR/UL (377)

OAL

GHAIR/L-GI f1 HF

Bars with Coolant Holes

for Internal Grooving and LH

Turning Adapters DMIN DCONMS

DMIN WF Right-hand shown

CDX LF (assembly) • LF(assembly)=OAL(holder)-f1+WF(adapter)

• For WF(adapter) dimension, see GAIR/L adapters

Designation DCONMS LH OAL WF HF f1 Adapter

GHAIR 25.4-32 1.000 1.000 8.000 .730 .459 .120 GAIR/L 32.. SR 16-236 P T-15/5 PL 100

GHAIR/L 31.7-32 1.250 1.250 8.000 .850 .569 .120 GAIR/L 32.. SR 16-236 P T-15/5 PL 125

GHAIR 31.7-40 1.250 1.500 8.000 .940 .569 .120 GAIR/L 40.. SR 16-212 T-20/5 SR 14-519 PL 125

• For DMIN & CDX refer to GAIR/L adapters

For tools, see pages: GAIR/L (370)

369