Page 121 - Turning_catalog_INCH_2022_45_P261-508

P. 121

CWN-CWX

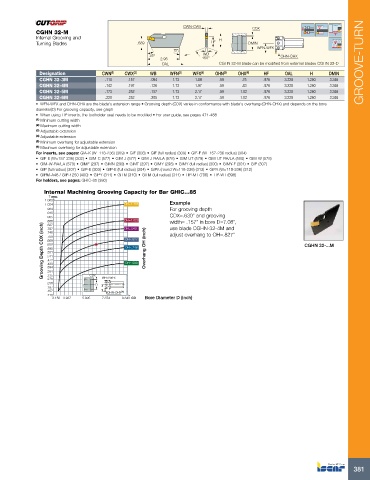

CGHN 32-M CDX

Internal Grooving and H

Turning Blades .689 HF DMIN

15° WFN-WFX

25° WB OHN-OHX

2.95 150°

OAL CGHN 32-M blade can be modified from external blades CGHN 32-D GROOVE-TURN

Designation CWN (1) CWX (2) WB WFN (3) WFX (4) OHN (5) OHX (6) HF OAL H DMIN

CGHN 32-3M .110 .157 .094 1.73 1.89 .59 .75 .976 3.228 1.260 3.346

CGHN 32-4M .142 .197 .126 1.73 1.97 .59 .83 .976 3.228 1.260 3.346

CGHN 32-5M .173 .252 .157 1.73 2.17 .59 1.02 .976 3.228 1.260 3.346

CGHN 32-6M .220 .252 .205 1.73 2.17 .59 1.02 .976 3.228 1.260 3.346

• WFN-WFX and OHN-OHX are the blade's extension range • Grooving depth (CDX) varies in conformance with blade's overhang (OHN-OHX) and depends on the bore

diameter(D) For grooving capacity, see graph

• When using TIP inserts, the toolholder seat needs to be modified • For user guide, see pages 471-488

(1) Minimum cutting width

(2) Maximum cutting width

(3) Adjustable extension

(4) Adjustable extension

(5) Minimum overhang for adjustable extension

(6) Maximum overhang for adjustable extension

For inserts, see pages: GIA-K (W=118-236) (309) • GIF (308) • GIF (full radius) (309) • GIF-E (W=157-236 radius) (304)

• GIF-E (W=157-236) (302) • GIM-C (577) • GIM-J (577) • GIM-J-RA/LA (578) • GIM-UT (579) • GIM-UT-RA/LA (580) • GIM-W (578)

• GIM-W-RA/LA (579) • GIMF (297) • GIMN (299) • GIMT (297) • GIMY (298) • GIMY (full radius) (300) • GIMY-F (301) • GIP (307)

• GIP (full radius) (307) • GIP-E (303) • GIP-E (full radius) (304) • GIPA (round W=118-236) (313) • GIPA (W=118-236) (312)

• GIPM-A46 / GIP-1250 (400) • GIPY (311) • GITM (310) • GITM (full radius) (311) • TIP-MT (706) • TIP-WT (698)

For holders, see pages: GHIC-85 (380)

Internal Machining Grooving Capacity for Bar GHIC...85

T max

1.063

1.024 OH=1.181 Example

.984 For grooving depth

.945

.905 CDX=.630” and grooving

.866 OH=1.023 width= .157” in bore D=7.08”,

Grooving Depth CDX (inch) .709 OH=.827 Overhang OH (inch) CGHN 32-...M

.827

use blade CGHN-32-4M and

OH=.945

.787

.748

adjust overhang to OH=.827”

.669

.630

OH=.748

.590

.551

.511

.472

OH=.590

.433

.394

.354

.315

.276

.236 CDX D WFN-WFX

.197

.157 OHN-OHX (1)

.118

3.150 3.937 5.905 7.874 9.843 ØD Bore Diameter D (inch)

381