Page 117 - Turning_catalog_INCH_2022_45_P261-508

P. 117

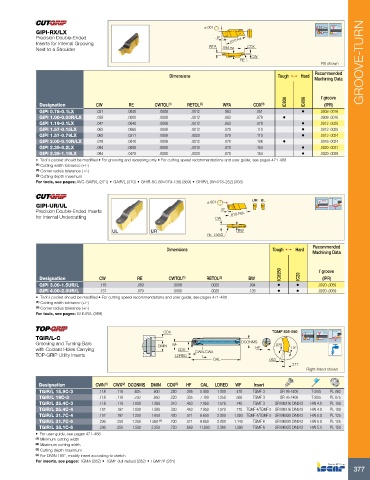

GIPI-RX/LX ±.001

Precision Double-Ended 8° .618 Ref.

Inserts for Internal Grooving

Next to a Shoulder WFA .094 Ref. CDX

CW

RE

RX shown GROOVE-TURN

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 IC808 f groove

Designation CW RE CWTOL (1) RETOL (2) WFA CDX (3) (IPR)

GIPI 0.78-0.1LX .031 .0040 .0008 .0012 .063 .051 • .0008-.0016

GIPI 1.00-0.00R/LX .039 .0000 .0008 .0012 .063 .079 • .0008-.0016

GIPI 1.19-0.1LX .047 .0040 .0008 .0012 .063 .079 • .0012-.0020

GIPI 1.57-0.15LX .062 .0060 .0008 .0012 .070 .110 • .0012-.0020

GIPI 1.57-0.79LX .062 .0311 .0008 .0020 .070 .110 • .0012-.0024

GIPI 2.00-0.10R/LX .079 .0040 .0008 .0012 .070 .106 • .0016-.0024

GIPI 2.39-0.2LX .094 .0080 .0008 .0012 .070 .154 • .0020-.0031

GIPI 2.39-1.19LX .094 .0470 .0008 .0020 .070 .154 • .0020-.0039

• Tool's pocket should be modified • For grooving and recessing only • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: AVC-GAIR/L (371) • GAIR/L (370) • GHIR-SC (W=079-138) (369) • GHIR/L (W=078-252) (368)

UR UL

GIPI-UR/UL ±.001

Precision Double-Ended Inserts 8° .618 Ref.

for Internal Undercutting CW

BW

RE=CW/2

Recommended

Dimensions Tough 1 Hard

Machining Data

IC8250 f groove

Designation CW RE CWTOL (1) RETOL (2) BW IC20 (IPR)

GIPI 3.00-1.5UR/L .118 .059 .0008 .0020 .094 • • .0020-.0059

GIPI 4.00-2.0UR/L .157 .079 .0008 .0020 .126 • • .0020-.0059

• Tool's pocket should be modified • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: GHIUR/L (369)

CDX TGMF 635-080

TGIR/L-C

Grooving and Turning Bars DMIN WF DCONMS .020

with Coolant Holes Carrying CDX CWN-CWX HF 19°

TOP-GRIP Utility Inserts LDRED

OAL .063

.217

Right-hand shown

Designation CWN (1) CWX (2) DCONMS DMIN CDX (3) HF OAL LDRED WF Insert

TGIR/L 15.9C-3 .118 .118 .625 .800 .220 .295 5.900 1.000 .470 TGMF 3 SR 76-1400 T-20/5 PL 062

TGIR/L 19C-3 .118 .118 .750 .950 .220 .335 7.100 1.250 .560 TGMF 3 SR 76-1400 T-20/5 PL 075

TGIR/L 25.4C-3 .118 .118 1.000 1.260 .310 .453 7.850 1.570 .740 TGMF 3 SR M5X16 DIN912 HW 4.0 PL 100

TGIR/L 25.4C-4 .157 .197 1.000 1.280 .330 .453 7.850 1.570 .770 TGMF 4/TGMF 5 SR M5X16 DIN912 HW 4.0 PL 100

TGIR/L 31.7C-4 .157 .197 1.250 1.650 .430 .571 8.650 2.000 1.000 TGMF 4/TGMF 5 SR M6X20 DIN912 HW 5.0 PL 125

TGIR/L 31.7C-6 .236 .250 1.250 1.850 (4) .700 .571 8.650 2.000 1.140 TGMF 6 SR M6X20 DIN912 HW 5.0 PL 125

TGIR/L 38.1C-6 .236 .250 1.500 2.250 .720 .669 11.800 2.360 1.390 TGMF 6 SR M6X25 DIN912 HW 5.0 PL 150

• For user guide, see pages 471-488

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

(4) For DMIN 185", modify insert according to sketch

For inserts, see pages: TGMA (282) • TGMF (full radius) (282) • TGMF/P (281)

377