Page 116 - Turning_catalog_INCH_2022_45_P261-508

P. 116

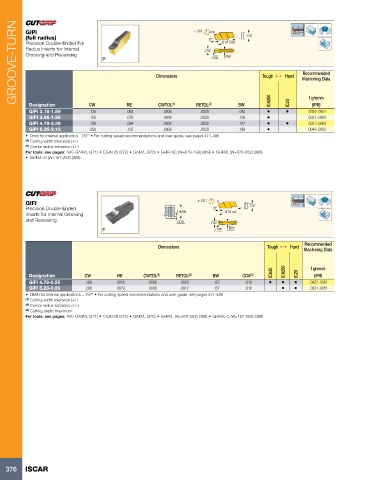

GROOVE-TURN GIPI Dimensions ±.001 CW 8° RE .618 Ref. .197 Tough 1 Hard Machining Data

(full radius)

Precision Double-Ended Full

Radius Inserts for Internal

Grooving and Recessing

BW

Recommended

f groove

CW

Designation

(IPR)

RE

BW

.0020

GIPI 3.18-1.59 .125 .063 CWTOL (1) RETOL (2) .094 • IC8250 • IC20 .0024-.0051

.0008

GIPI 3.96-1.98 .156 .078 .0008 .0020 .126 • .0031-.0063

GIPI 4.78-2.39 .188 .094 .0008 .0020 .157 • • .0031-.0063

GIPI 6.35-3.18 .250 .125 .0008 .0020 .189 • .0043-.0083

• Dmin for internal application= 787" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: AVC-GAIR/L (371) • CGIN 26 (372) • GAIR/L (370) • GHIR-SC (W=079-138) (369) • GHIR/L (W=078-252) (368)

• GHIR/L-C (W=157-252) (368)

GIFI ±.001

Precision Double-Ended DMIN 8° .197

Inserts for Internal Grooving .618 Ref.

and Recessing CDX CW

RE BW

Recommended

Dimensions Tough 1 Hard

Machining Data

(IPR)

Designation CW RE CWTOL (1) RETOL (2) BW CDX (3) IC830 IC8250 IC20 f groove

GIFI 4.78-0.55 .188 .0216 .0008 .0020 .157 .610 • • • .0027-.0051

GIFI 5.28-0.20 .208 .0079 .0008 .0012 .157 .610 • • .0031-.0051

• DMIN for internal applications = 787" • For cutting speed recommendations and user guide, see pages 471-488

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: AVC-GAIR/L (371) • CGIN 26 (372) • GAIR/L (370) • GHIR/L (W=078-252) (368) • GHIR/L-C (W=157-252) (368)

376 ISCAR