Page 26 - Turning_catalog_INCH_2022_45_P509-690

P. 26

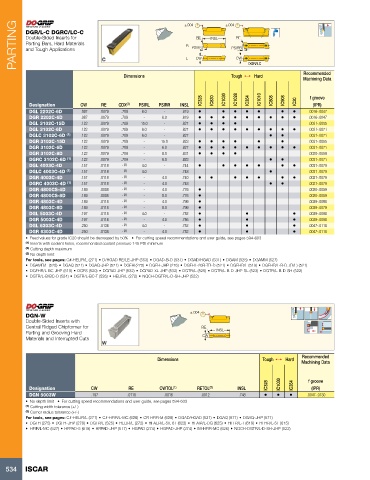

PARTING DGR/L-C DGRC/LC-C ±.004 PSIRR INSL ±.004 CW

Double-Sided Inserts for

RE

RE

Parting Bars, Hard Materials

R

PSIRR

and Tough Applications

CW

L

DGR/LC

Dimensions Tough 1 Hard Recommended

Machining Data

IC328 IC830 IC1030 IC1028 IC354 IC1010 IC808 IC908 IC20 f groove

Designation CW RE CDX (2) PSIRL PSIRR INSL (IPR)

DGL 2202C-6D .087 .0079 .709 6.0 - .819 • • • • • • • .0016-.0047

DGR 2202C-6D .087 .0079 .709 - 6.0 .819 • • • • • • • • • .0016-.0047

DGL 3102C-15D .122 .0079 .709 15.0 - .827 • • • • .0031-.0055

DGL 3102C-6D .122 .0079 .709 6.0 - .827 • • • • • • • • • .0031-.0071

DGLC 3102C-6D (1) .122 .0079 .709 6.0 - .827 • • .0031-.0071

DGR 3102C-15D .122 .0079 .709 - 15.0 .823 • • • • • • .0031-.0055

DGR 3102C-6D .122 .0079 .709 - 6.0 .827 • • • • • • • • • .0031-.0071

DGR 3102C-8D .122 .0079 .709 - 8.0 .831 • • • • .0020-.0059

DGRC 3102C-6D (1) .122 .0079 .709 - 6.0 .823 • • .0031-.0071

DGL 4003C-4D .157 .0118 - (3) 4.0 - .744 • • • • • • • .0031-.0079

(3)

DGLC 4003C-4D (1) .157 .0118 - 4.0 - .748 • .0031-.0079

(3)

DGR 4003C-4D .157 .0118 - - 4.0 .740 • • • • • • • .0031-.0079

(3)

DGRC 4003C-4D (1) .157 .0118 - - 4.0 .748 • • .0031-.0079

DGR 4800CS-4D .189 .0008 - - 4.0 .776 • .0020-.0059

(3)

(3)

DGR 4800CS-8D .189 .0008 - - 8.0 .776 • .0020-.0059

DGR 4803C-4D .189 .0118 - - 4.0 .799 • .0039-.0098

(3)

(3)

DGR 4803C-8D .189 .0118 - - 8.0 .799 • .0039-.0079

DGL 5003C-4D .197 .0118 - 4.0 - .752 • • • .0039-.0098

(3)

DGR 5003C-4D .197 .0118 - - 4.0 .756 • • • .0039-.0098

(3)

DGL 6303C-4D .250 .0138 - 4.0 - .752 • • • .0047-.0118

(3)

DGR 6303C-4D .250 .0138 - - 4.0 .752 • • • .0047-.0118

(3)

• Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 594-603

(1) Inserts with coolant holes, recommended coolant pressure 145 PSI minimum

(2) Cutting depth maximum

(3) No depth limit

For tools, see pages: C#-HELIR/L (271) • D/HGAD RE/LE-JHP (553) • DGAD-B-D (531) • DGAD/HGAD (531) • DGAM (528) • DGAMM (527)

• DGAMR/L (528) • DGAQ (571) • DGAQ-JHP (571) • DGFH (275) • DGFH-JHP (276) • DGFHL-26B-TR-D (521) • DGFHR/L (519) • DGFHR/L-B-D..(R/L) (521)

• DGFHR/L-BC-JHP (519) • DGFS (520) • DGPAD-JHP (532) • DGPAD-XL-JHP (532) • DGTR/L (525) • DGTR/L-B-D-JHP-SL (523) • DGTR/L-B-D-SH (522)

• DGTR/L-B/BC-D (524) • DGTR/L-BC-T (526) • HELIR/L (272) • NQCH-DGTR/L-D-SH-JHP (522)

DGN-W ±.004

Double-Sided Inserts with

Central Ridged Chipformer for RE INSL

Parting and Grooving Hard CW

Materials and Interrupted Cuts

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC1030 IC354 f groove

Designation CW RE CWTOL (1) RETOL (2) INSL (IPR)

DGN 5003W .197 .0118 .0016 .0012 .748 • • • .0047-.0130

• No depth limit • For cutting speed recommendations and user guide, see pages 594-603

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: C#-HELIR/L (271) • C#-HFIR/L-MC (626) • CR HFIR-M (628) • DGAD/HGAD (531) • DGAQ (571) • DGAQ-JHP (571)

• DGFH (275) • DGFH-JHP (276) • DGTR/L (525) • HELIR/L (272) • HFAER/L-5T, 6T (622) • HFAIR/L-DG (625) • HFFR/L-T (619) • HFHR/L-5T (615)

• HFIR/L-MC (627) • HFPAD-5 (618) • HFPAD-JHP (617) • HGPAD (274) • HGPAD-JHP (274) • IM-HFIR-MC (626) • NQCH-DGTR/L-D-SH-JHP (522)

534 ISCAR