Page 80 - Turning_catalog_INCH_2022_45_P509-690

P. 80

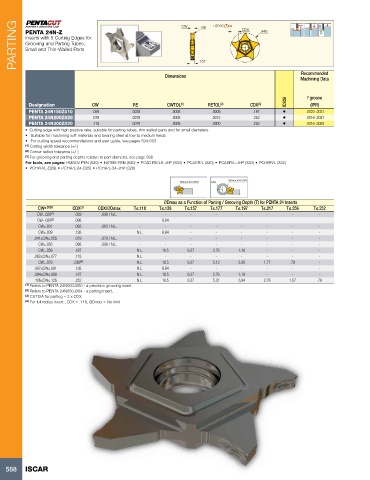

PARTING PENTA 24N-Z CW RE ±.0016 CDX .945

Inserts with 5 Cutting Edges for

Grooving and Parting Tubes,

Small and Thin-Walled Parts

Dimensions .157 Recommended

Machining Data

IC908 f groove

Designation CW RE CWTOL (1) RETOL (2) CDX (3) (IPR)

PENTA 24N150Z010 .059 .0039 .0008 .0008 .197 • .0020-.0031

PENTA 24N200Z020 .079 .0079 .0008 .0012 .252 • .0016-.0047

PENTA 24N300Z020 .118 .0079 .0008 .0000 .252 • .0016-.0063

• Cutting edge with high positive rake, suitable for parting tubes, thin walled parts and for small diameters

• Suitable for machining soft materials and bearing steel at low to medium feeds

• For cutting speed recommendations and user guide, see pages 594-603

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) For grooving and parting depths relative to part diameter, see page 588

For tools, see pages: HMSDV PEN (530) • HSTBS-PEN (530) • PCAD RE/LE-JHP (553) • PCADR/L (330) • PCADR/L-JHP (330) • PCHBR/L (332)

• PCHPR/L (329) • PCHR/L-24 (325) • PCHR/L-24-JHP (326)

ØDmax (CUTDIA)

ØDmax (CUTDIA) CDX

ØDmax as a Function of Parting / Grooving Depth (T) for PENTA 24 Inserts

CW ±.0008 CDX (3) CDX/ØDmax T≤.118 T≤.138 T≤.157 T≤.177 T≤.197 T≤.217 T≤.256 T≤.252

CW=.020 (1) .039 .039 / N.L. - - - - - - - -

CW=.020 (2) .098 9.84

CW=.031 .063 .063 / N.L. - - - - - - - -

CW=.039 .138 N.L. 9.84 - - - - - -

.041≤CW≤.055 .079 .079 / N.L. - - - - - - - -

CW=.058 .098 .098 / N.L. - - - - - - - -

CW=.059 .197 N.L. 18.5 8.27 2.76 1.18 - - -

.062≤CW≤.077 .118 N.L. - - - - - - -

CW=.079 .236 (4) N.L. 18.5 8.27 5.12 2.95 1.77 .79 -

.087≤CW≤.091 .138 N.L. 9.84 - - - - - -

.094≤CW≤.098 .197 N.L. 18.5 8.27 2.76 1.18 - - -

.106≤CW≤.125 .252 N.L. 18.5 8.27 5.31 3.94 2.76 1.57 .79

(1) Refers to PENTA 24N050J000 - a precision grooving insert.

(2) Refers to PENTA 24N050J004 - a parting insert.

(3) CUTDIA for parting = 2 x CDX

For full radius insert , CDX = .118, ØDmax = No limit

(4)

588 ISCAR