Page 102 - Aluminum_Machining_catalog_2023

P. 102

Rd°

SOLID CARBIDE CUTTERS

RE

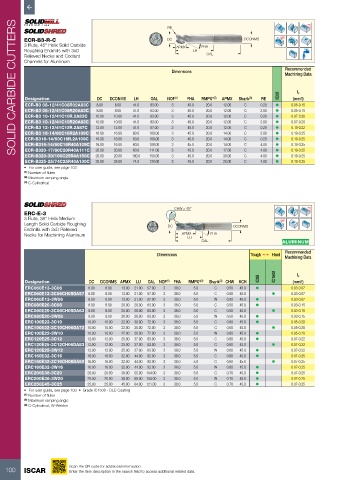

ECR-B3-R-C DC DCONMS

3 Flute, 45° Helix Solid Carbide APMX FHA

Roughing Endmills with 3xD LH

Relieved Necks and Coolant OAL

Channels for Aluminum

Dimensions Recommended

Machining Data

IC08 fz

Designation DC DCONMS LH OAL NOF (1) FHA RMPX° (2) APMX Shank (3) RE (mm/t)

ECR-B3 08-12/41C08R02A83C 8.00 8.00 41.0 83.00 3 45.0 20.0 12.00 C 0.20 • 0.05-0.15

ECR-B3 08-12/41C08R20A83C 8.00 8.00 41.0 83.00 3 45.0 20.0 12.00 C 2.00 • 0.05-0.15

ECR-B3 10-12/41C10R.2A83C 10.00 10.00 41.0 83.00 3 45.0 20.0 12.00 C 0.20 • 0.07-0.20

ECR-B3 10-12/41C10R20A83C 10.00 10.00 41.0 83.00 3 45.0 20.0 12.00 C 2.00 • 0.07-0.20

ECR-B3 12-12/41C12R.2A87C 12.00 12.00 41.0 87.00 3 45.0 20.0 12.00 C 0.20 • 0.10-0.22

ECR-B3 16-14/60C16R2A109C 16.00 16.00 60.0 109.00 3 45.0 20.0 14.00 C 2.00 • 0.10-0.25

ECR-B316-14/60C16R.2A109C 16.00 16.00 60.0 109.00 3 45.0 20.0 14.00 C 0.20 • 0.10-0.25

ECR-B316-14/60C16R40A109C 16.00 16.00 60.0 109.00 3 45.0 20.0 14.00 C 4.00 • 0.10-0.25

ECR-B320-17/60C20R40A111C 20.00 20.00 60.0 111.00 3 45.0 20.0 17.00 C 4.00 • 0.10-0.25

ECR-B320-30/100C25R4A150C 20.00 20.00 100.0 150.00 3 45.0 20.0 30.00 C 4.00 • 0.10-0.25

ECR-B325-25/74C25R40A130C 25.00 25.00 74.0 130.00 3 45.0 20.0 25.00 C 4.00 • 0.10-0.25

• For user guide, see page 103

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical

Rd°

ERC-E-3 CHW x 45°

3 Flute, 38° Helix Medium

Length Solid Carbide Roughing DC DCONMS

Endmills with 3xD Relieved

Necks for Machining Aluminum APMX FHA

LU

OAL ALUMINUM

Dimensions Tough 1 Hard Recommended

Machining Data

IC08 IC1508 fz

Designation DC DCONMS APMX LU OAL NOF (1) FHA RMPX° (2) Shank (3) CHW KCH (mm/t)

ERC060E13-3C06 6.00 6.00 13.00 21.00 57.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.07

ERC060E13-3C06CH05DA57 6.00 6.00 13.00 21.00 57.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.07

ERC060E13-3W06 6.00 6.00 13.00 21.00 57.00 3 38.0 5.0 W 0.50 45.0 • 0.03-0.07

ERC080E20-3C08 8.00 8.00 20.00 28.00 63.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.15

ERC080E20-3C08CH05DA63 8.00 8.00 20.00 28.00 63.00 3 38.0 5.0 C 0.50 45.0 • 0.03-0.15

ERC080E20-3W08 8.00 8.00 20.00 28.00 63.00 3 38.0 5.0 W 0.50 45.0 • 0.03-0.15

ERC100E22-3C10 10.00 10.00 22.00 30.00 72.00 3 38.0 5.0 C 0.60 45.0 • 0.05-0.20

ERC100E22-3C10CH06DA72 10.00 10.00 22.00 30.00 72.00 3 38.0 5.0 C 0.60 45.0 • 0.05-0.20

ERC100E22-3W10 10.00 10.00 22.00 30.00 72.00 3 38.0 5.0 W 0.60 45.0 • 0.05-0.20

ERC120E25-3C12 12.00 12.00 25.00 37.00 83.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.22

ERC120E25-3C12CH06DA83 12.00 12.00 25.00 37.00 83.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.22

ERC120E25-3W12 12.00 12.00 25.00 37.00 83.00 3 38.0 5.0 W 0.60 45.0 • 0.07-0.22

ERC160E32-3C16 16.00 16.00 32.00 44.00 92.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.25

ERC160E32-3C16CH06DA92 16.00 16.00 32.00 44.00 92.00 3 38.0 5.0 C 0.60 45.0 • 0.07-0.25

ERC160E32-3W16 16.00 16.00 32.00 44.00 92.00 3 38.0 5.0 W 0.60 45.0 • 0.07-0.25

ERC200E38-3C20 20.00 20.00 38.00 55.00 104.00 3 38.0 5.0 C 0.70 45.0 • 0.07-0.25

ERC200E38-3W20 20.00 20.00 38.00 55.00 104.00 3 38.0 5.0 W 0.70 45.0 • 0.07-0.25

ERC250E45-3C25 25.00 25.00 45.00 64.00 121.00 3 38.0 5.0 C 0.70 45.0 • 0.07-0.25

• For user guide, see page 103 • Grade IC1508 - DLC Coating

(1) Number of flutes

(2) Maximum ramping angle

(3) C-Cylindrical, W-Weldon

100 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.