Page 106 - Aluminum_Machining_catalog_2023

P. 106

½

SOLID CARBIDE CUTTERS

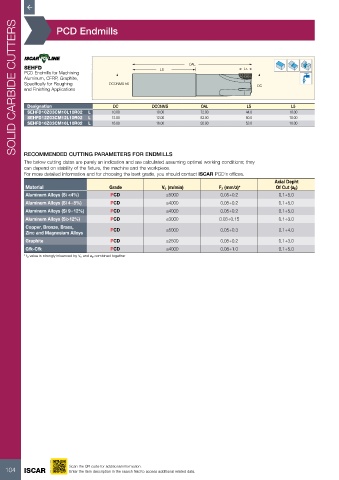

PCD Endmills

OAL

SEHFD LS L5

PCD Endmills for Machining

Aluminum, CFRP, Graphite,

Specifically for Roughing DCONMS h6 DC

and Finishing Applications

Designation DC DCONMS OAL LS L5

SEHFD10Z03CM10L10R02 L 10.00 10.00 72.00 44.0 10.00

SEHFD12Z03CM12L10R02 L 12.00 12.00 83.00 50.0 10.00

SEHFD16Z03CM16L10R02 L 16.00 16.00 92.00 53.0 10.00

RECOMMENDED CUTTING PARAMETERS FOR ENDMILLS

The below cutting datas are purely an indication and are calculated assuming optimal working conditions; they

can depend on stability of the fixture, the machine and the workpiece.

For more detailed information and for choosing the best grade, you should contact ISCAR PCD’s offices.

Axial Depht

Material Grade Vc (m/min) Fz (mm/z)* Of Cut (ap)

Aluminum Alloys (Si <4%) PCD ≤5000 0.05÷0.2 0.1÷5.0

Aluminum Alloys (Si 4÷8%) PCD ≤4000 0.05÷0.2 0.1÷5.0

Aluminum Alloys (Si 9÷12%) PCD ≤4000 0.05÷0.2 0.1÷5.0

Aluminum Alloys (Si>12%) PCD ≤3000 0.03÷0.15 0.1÷3.0

Copper, Bronze, Brass, PCD ≤5000 0.05÷0.3 0.1÷4.0

Zinc and Magnesium Alloys

Graphite PCD ≤2500 0.05÷0.2 0.1÷3.0

Gfk-Cfk PCD ≤4000 0.08÷1.0 0.1÷5.0

* fz value is strongly inluenced by Vc and ap combined together

104 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.