Page 126 - Aluminum_Machining_catalog_2023

P. 126

USER GUIDE

INTERCHANGEABLE HIGH PRECISION REAMING HEADS

Setting Methods

There are two optional setting methods - comparison

micrometer and setting device. Comparison micrometer

with dial gauge, although a low cost solution and readily

available for small workshops, is prone to damaging

the cutting edge and therefore not recommended.

Using a Comparison Micrometer

Set the micrometer to the correct diameter using the

precision blocks. Adjust the frontal diameter and back

taper by turning the adjustment screw clockwise.

The front diameter should be larger than the rear

diameter by approximately 0.015 mm.(0.6 µin).

Using a Setting Device

ISCAR’s mechanical setting device enables easy,

quick and accurate adjustment. Due to its modular

construction, it can be used for standard, special

and more complicated reamer adjustments.

Setting Device Located Between Centers

• shorter setting time

• modular system

• higher accuracy

• no risk of damaging the cutting edge

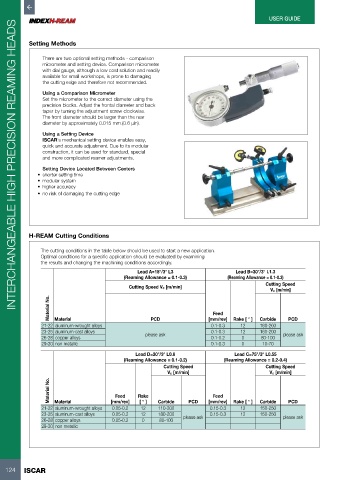

H-REAM Cutting Conditions

The cutting conditions in the table below should be used to start a new application.

Optimal conditions for a specific application should be evaluated by examining

the results and changing the machining conditions accordingly.

Lead A=15°/3° L3 Lead B=30°/3° L1.3

(Reaming Allowance = 0.1-0.3) (Reaming Allowance = 0.1-0.3)

Cutting Speed

Cutting Speed Vc [m/min]

Vc [m/min]

Material No. Feed

Material

21-22 aluminum-wrought alloys PCD [mm/rev] Rake [ ° ] Carbide PCD

12

160-200

0.1-0.3

23-25 aluminum-cast alloys please ask 0.1-0.3 12 160-200 please ask

26-28 copper alloys 0.1-0.2 0 80-100

29-30 non metallic 0.1-0.3 0 10-70

Lead D=30°/3° L0.6 Lead C=75°/3° L0.55

(Reaming Allowance = 0.1-0.2) (Reaming Allowance = 0.2-0.4)

Cutting Speed Cutting Speed

Vc [m/min] Vc [m/min]

Material No. Feed Rake Feed

Material

150-250

21-22 aluminum-wrought alloys [mm/rev] [ ° ] Carbide PCD [mm/rev] Rake [ ° ] Carbide PCD

12

12

0.05-0.2

0.15-0.3

110-200

23-25 aluminum-cast alloys 0.05-0.2 12 180-200 please ask 0.15-0.3 12 150-250 please ask

26-28 copper alloys 0.05-0.2 0 80-100

29-30 non metallic

124 ISCAR