Page 129 - Aluminum_Machining_catalog_2023

P. 129

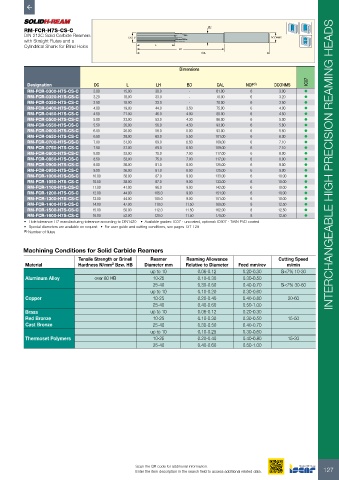

RM-FCR-H7S-CS-C BD

DIN 212C Solid Carbide Reamers DC H7 DCONMS

with Straight Flutes and a

Cylindrical Shank for Blind Holes L

LH

OAL

Dimensions

IC07

Designation DC L LH BD OAL NOF (1) DCONMS

RM-FCR-0300-H7S-CS-C 3.00 15.00 30.0 - 61.00 6 3.00 •

RM-FCR-0320-H7S-CS-C 3.20 18.00 33.0 - 70.00 6 3.20 •

RM-FCR-0350-H7S-CS-C 3.50 18.00 33.0 - 70.00 6 3.50 •

RM-FCR-0400-H7S-CS-C 4.00 19.00 44.0 3.50 75.00 6 4.00 •

RM-FCR-0450-H7S-CS-C 4.50 21.00 46.0 4.00 80.00 6 4.50 •

RM-FCR-0500-H7S-CS-C 5.00 23.00 53.0 4.30 86.00 6 5.00 •

RM-FCR-0550-H7S-CS-C 5.50 26.00 56.0 4.50 93.00 6 5.60 •

RM-FCR-0600-H7S-CS-C 6.00 26.00 56.0 5.00 93.00 6 5.60 •

RM-FCR-0650-H7S-CS-C 6.50 28.00 63.0 5.50 101.00 6 6.30 •

RM-FCR-0700-H7S-CS-C 7.00 31.00 69.0 6.50 109.00 6 7.10 •

RM-FCR-0750-H7S-CS-C 7.50 31.00 69.0 6.50 109.00 6 7.10 •

RM-FCR-0800-H7S-CS-C 8.00 33.00 75.0 7.00 117.00 6 8.00 •

RM-FCR-0850-H7S-CS-C 8.50 33.00 75.0 7.00 117.00 6 8.00 •

RM-FCR-0900-H7S-CS-C 9.00 36.00 81.0 8.00 125.00 6 9.00 • INTERCHANGEABLE HIGH PRECISION REAMING HEADS

RM-FCR-0950-H7S-CS-C 9.50 36.00 81.0 8.00 125.00 6 9.00 •

RM-FCR-1000-H7S-CS-C 10.00 38.00 87.0 9.00 133.00 6 10.00 •

RM-FCR-1050-H7S-CS-C 10.50 38.00 87.0 9.00 133.00 6 10.00 •

RM-FCR-1100-H7S-CS-C 11.00 41.00 96.0 9.00 142.00 6 10.00 •

RM-FCR-1200-H7S-CS-C 12.00 44.00 105.0 9.00 151.00 6 10.00 •

RM-FCR-1300-H7S-CS-C 13.00 44.00 105.0 9.00 151.00 6 10.00 •

RM-FCR-1400-H7S-CS-C 14.00 47.00 110.0 11.50 160.00 8 12.50 •

RM-FCR-1500-H7S-CS-C 15.00 50.00 112.0 11.50 162.00 8 12.50 •

RM-FCR-1600-H7S-CS-C 16.00 52.00 120.0 11.50 170.00 8 12.50 •

• Hole tolerance: H7 manufacturing tolerance according to DIN1420 • Available grades: IC07 - uncoated, optional: IC907 - TiAlN PVD coated

• Special diameters are available on request • For user guide and cutting conditions, see pages 127-129

(1) Number of flutes

Machining Conditions for Solid Carbide Reamers

Tensile Strength or Brinell Reamer Reaming Allowance Cutting Speed

2

Material Hardness N/mm Bzw. HB Diameter mm Relative to Diameter Feed mm/rev m/min

up to 10 0.06-0.12 0.20-0.30 Si<7% 10-30

Aluminum Alloy over 80 HB 10-25 0.10-0.30 0.30-0.50

25-40 0.30-0.50 0.40-0.70 Si<7% 30-60

up to 10 0.10-0.20 0.30-0.60

Copper 10-25 0.20-0.40 0.40-0.80 20-60

25-40 0.40-0.60 0.50-1.00

Brass up to 10 0.06-0.12 0.20-0.30

Red Bronze 10-25 0.10-0.30 0.30-0.50 15-50

Cast Bronze 25-40 0.30-0.50 0.40-0.70

up to 10 0.10-0.25 0.30-0.60

Thermoset Polymers 10-25 0.20-0.40 0.40-0.80 15-30

25-40 0.40-0.60 0.50-1.00

Scan the QR code for additional information.

Enter the item description in the search field to access additional related data. 127