Page 86 - Aluminum_Machining_catalog_2023

P. 86

W1 Rd°

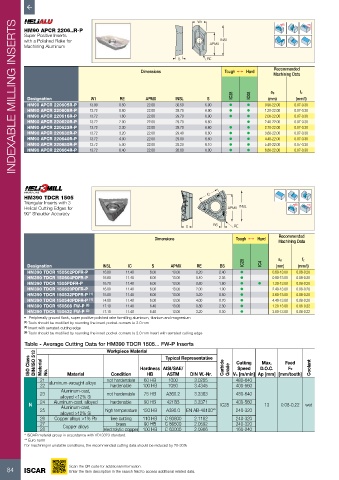

INDEXABLE MILLING INSERTS

HM90 APCR 2206..R-P

Super Positive Inserts

with a Polished Rake for lNSL

Machining Aluminum APMX

S RE

Dimensions Tough 1 Hard Recommended

Machining Data

IC28 IC08 ap fz

Designation W1 RE APMX INSL S (mm) (mm/t)

HM90 APCR 220605R-P 13.90 0.50 22.00 30.50 6.90 • • 0.90-22.00 0.07-0.30

HM90 APCR 220608R-P 13.72 0.80 22.00 29.70 6.90 • • 1.20-22.00 0.07-0.30

HM90 APCR 220616R-P 13.72 1.60 22.00 29.70 6.90 • • 2.00-22.00 0.07-0.30

HM90 APCR 220620R-P 13.72 2.00 22.00 29.70 6.60 • 2.40-22.00 0.07-0.30

HM90 APCR 220623R-P 13.72 2.30 22.00 29.70 6.60 • • 2.70-22.00 0.07-0.30

HM90 APCR 220632R-P 13.72 3.20 22.00 29.40 6.60 • • 3.60-22.00 0.07-0.30

HM90 APCR 220640R-P 13.72 4.00 22.00 29.00 6.60 • • 4.40-22.00 0.07-0.30

HM90 APCR 220650R-P 13.72 5.00 22.00 28.20 6.10 • • 5.40-22.00 0.07-0.30

HM90 APCR 220664R-P 13.72 6.40 22.00 26.80 6.00 • • 6.80-22.00 0.07-0.30

HM390 TDCR 1505 IC

Triangular Inserts with 3 Rd°

Helical Cutting Edges for APMX INSL

90° Shoulder Accuracy

S BS RE

Recommended

Dimensions Tough 1 Hard

Machining Data

ap

fz

Designation INSL IC S APMX RE BS IC28 IC4 (mm) (mm/t)

HM390 TDCR 150502PDFR-P 16.80 11.40 6.00 13.00 0.20 2.40 • 0.60-13.00 0.08-0.20

HM390 TDCR 150504PDFR-P 16.80 11.40 6.00 13.00 0.40 2.35 • 0.80-13.00 0.08-0.20

HM390 TDCR 1505PDFR-P 16.70 11.40 6.00 13.00 0.80 1.60 • • 1.20-13.00 0.08-0.20

HM390 TDCR 150520PDFR-P 16.00 11.40 6.00 13.00 2.00 1.00 • 2.40-13.00 0.08-0.20

HM390 TDCR 150532PDFR-P (1) 15.00 11.40 6.00 13.00 3.20 0.50 • 3.60-13.00 0.08-0.20

HM390 TDCR 150540PDFR-P (1) 14.00 11.40 6.00 13.00 4.00 0.70 • 4.40-13.00 0.08-0.20

HM390 TDCR 150508 FW-P (2) 17.10 11.40 6.40 13.00 0.80 2.30 • 1.20-13.00 0.08-0.22

HM390 TDCR 150532 FW-P (3) 17.10 11.40 6.40 13.00 3.20 0.50 • 3.60-13.00 0.08-0.22

• Peripherally ground flank, super positive polished rake formilling aluminum, titanium and magnesium

(1) Tools should be modified by rounding the insert pocket corners to 2.0 mm

(2) Insert with serrated cutting edge

(3) Tools should be modified by rounding the insert pocket corners to 2.0 mm Insert with serrated cutting edge

Table - Average Cutting Data for HM390 TDCR 1505... FW-P Inserts

Workpiece Material

Typical Representative

ISO Class DIN/ISO 513 Material No. Hardness AISI/SAE/ Carbide Grade Cutting D.O.C. Feed Coolant

Max.

Speed

Fz

HB

Condition

Material

3.0255

1000

21 aluminum-wrought alloys not hardenable 60 HB ASTM DIN W.-Nr. Vc [m/min] Ap [mm] [mm/tooth]

480-640

22 hardenable 100 HB 7050 3.4345 400-560

Aluminum-cast,

23 not hardenable 75 HB A360.2 3.2383 480-640

alloyed <12% Si

N 24 Aluminum-cast, alloyed hardenable 90 HB 4218B 3.2371 IC28 400-560 13 0.08-0.22 wet

Aluminum-cast,

25 high temperature 130 HB A390.0 EN AB-48100** 240-320

alloyed >12% Si

26 Copper alloys >1% Pb free cutting 110 HB C 93800 2.1182 240-320

27 brass 90 HB C 86500 2.0592 240-320

28 Copper alloys electrolytic copper 100 HB C 63000 2.0966 160-240

* ISCAR material group in accordance with VDI 3323 standard

** Euro norm

For machining in unstable conditions, the recommended cutting data should be reduced by 20-30%

84 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.