Page 96 - Aluminum_Machining_catalog_2023

P. 96

Rd°

MULTI-MASTER - SOLID CARBIDE INTERCHANGEABLE MILLING HEADS

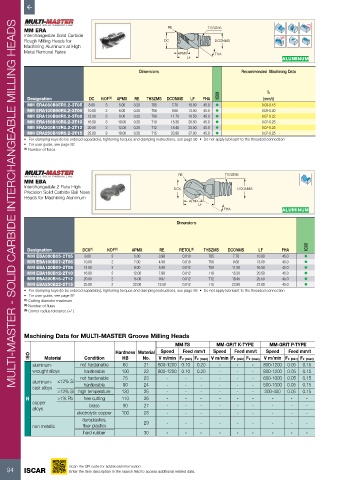

MM ERA RE THSZMS

Interchangeable Solid Carbide

Rough Milling Heads for DC DCONMS

Machining Aluminum at High

Metal Removal Rates APMX FHA

LF ALUMINUM

Dimensions Recommended Machining Data

IC08 fz

Designation DC NOF (1) APMX RE THSZMS DCONMS LF FHA (mm/t)

MM ERA080B05R0.2-3T05 8.00 3 5.00 0.20 T05 7.70 10.00 45.0 • 0.03-0.15

MM ERA100B06R0.2-3T06 10.00 3 6.00 0.20 T06 9.60 13.00 45.0 • 0.05-0.20

MM ERA120B08R0.2-3T08 12.00 3 8.00 0.20 T08 11.70 16.50 45.0 • 0.07-0.22

MM ERA160B10R0.2-3T10 16.00 3 10.00 0.20 T10 15.30 20.50 45.0 • 0.07-0.25

MM ERA200B12R0.2-3T12 20.00 3 12.00 0.20 T12 18.45 25.50 45.0 • 0.07-0.25

MM ERA250B19R0.2-3T15 25.00 3 19.00 0.20 T15 23.90 37.00 45.0 • 0.07-0.25

• For clamping keys (to be ordered separately), tightening torques and clamping instructions, see page 95 • Do not apply lubricant to the threaded connection

• For user guide, see page 92

(1) Number of flutes

RE THSZMS

MM EBA

Interchangeable 2 Flute High DCX DCONMS

Precision Solid Carbide Ball Nose

Heads for Machining Aluminum

APMX

LF

FHA ALUMINUM

Dimensions

Designation DCX (1) NOF (2) APMX RE RETOL (3) THSZMS DCONMS LF FHA IC08

MM EBA080B05-2T05 8.00 2 5.00 3.98 0.010 T05 7.70 10.00 45.0 •

MM EBA100B07-2T06 10.00 2 7.00 4.98 0.010 T06 9.60 13.00 45.0 •

MM EBA120B09-2T08 12.00 2 9.00 5.98 0.012 T08 11.50 16.50 45.0 •

MM EBA160B12-2T10 16.00 2 12.00 7.98 0.012 T10 15.30 20.50 45.0 •

MM EBA200B15-2T12 20.00 2 15.00 9.97 0.012 T12 18.45 25.50 45.0 •

MM EBA250B22-2T15 25.00 2 22.00 12.50 0.012 T15 23.90 37.00 45.0 •

• For clamping keys (to be ordered separately), tightening torques and clamping instructions, see page 95 • Do not apply lubricant to the threaded connection

• For user guide, see page 92

(1) Cutting diameter maximum

(2) Number of flutes

(3) Corner radius tolerance (+/-)

Machining Data for MULTI-MASTER Groove Milling Heads

MM-TS MM-GRIT K-TYPE MM-GRIT P-TYPE

Hardness Material Speed Feed mm/t Speed Feed mm/t Speed Feed mm/t

ISO Material Condition HB No. V m/min Fz (min) Fz (max) V m/min Fz (min) Fz (max) V m/min Fz (min) Fz (max)

aluminum- not hardenable 60 21 800-1200 0.10 0.20 - - - 800-1200 0.05 0.15

wrought alloys hardenable 100 22 800-1200 0.10 0.20 - - - 800-1200 0.05 0.15

not hardenable 75 23 - - - - - - 600-1000 0.05 0.15

aluminum- ≤12% Si hardenable 90 24 - - - - - - 500-1000 0.05 0.15

cast alloys

>12% Si high temperature 130 25 - - - - - - 200-400 0.05 0.15

N >1% Pb free cutting 110 26 - - - - - - - - -

copper brass 90 27 - - - - - - - - -

alloys

electrolytic copper 100 28 - - - - - - - - -

duroplastics, 29 - - - - - - - - -

non metallic fiber plastics

hard rubber 30 - - - - - - - - -

94 ISCAR Scan the QR code for additional information.

Enter the item description in the search field to access additional related data.