Page 432 - THREADING CATALOG

P. 432

USER GUIDE

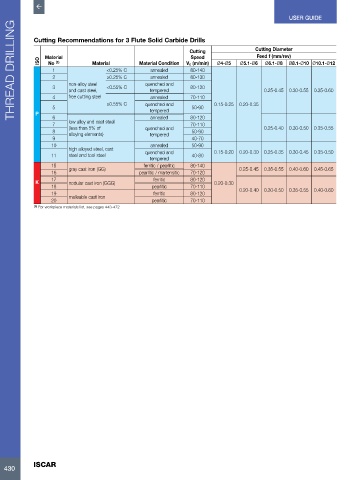

THREAD DRILLING ISO Material non-alloy steel <0.25% C Material Condition Vc (m/min) Ø4-Ø5 Ø5.1-Ø6 Cutting Diameter 0.35-0.60

Cutting Recommendations for 3 Flute Solid Carbide Drills

Cutting

Feed f (mm/rev)

Speed

No

Material

Ø8.1-Ø10 Ø10.1-Ø12

Ø6.1-Ø8

(1)

1

80-140

annealed

2

80-130

≥0.25% C

annealed

quenched and

3

80-120

<0.55% C

0.30-0.55

and cast steel,

0.25-0.45

tempered

free cutting steel

annealed

4

70-110

≥0.55% C

50-90

tempered

P

annealed

7 5 6 low alloy and cast steel quenched and 80-120 0.15-0.25 0.20-0.35 0.25-0.40 0.30-0.50 0.35-0.55

70-110

(less than 5% of

8 alloying elements) quenched and 50-90

tempered

9 40-70

10 annealed 50-90

high alloyed steel, cast

11 steel and tool steel quenched and 40-80 0.15-0.20 0.20-0.30 0.25-0.35 0.30-0.45 0.35-0.50

tempered

15 gray cast iron (GG) ferritic / pearlitic 80-140 0.25-0.45 0.35-0.55 0.40-0.60 0.45-0.65

16 pearlitic / martensitic 70-120

K 17 nodular cast iron (GGG) ferritic 80-120 0.20-0.30

18 pearlitic 70-110 0.20-0.40 0.30-0.50 0.35-0.55 0.40-0.60

19 malleable cast iron ferritic 80-120

20 pearlitic 70-110

(1) For workpiece materials list, see pages 443-472

ISCAR

430