Page 116 - HOLE MAKING CATALOG p185-310

P. 116

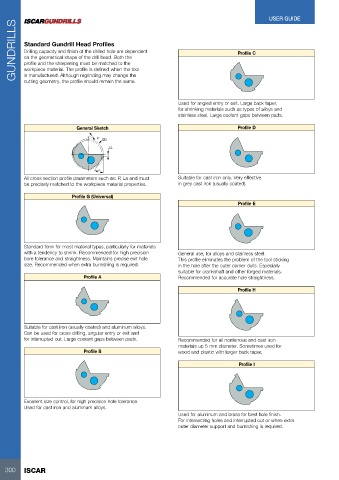

GUNDRILLS Standard Gundrill Head Profiles USER GUIDE

Drilling capacity and finish of the drilled hole are dependent Profile C

on the geometrical shape of the drill head. Both the

profile and the sharpening must be matched to the Used for angled entry or exit. Large back taper,

workpiece material. The profile is defined when the tool for shrinking materials such as types of alloys and

is manufactured. Although regrinding may change the stainless steel. Large coolant gaps between pads.

cutting geometry, the profile should remain the same.

Profile D

General Sketch

Suitable for cast iron only. Very effective

P ØD in grey cast iron (usually coated).

La

Profile E

α

All cross section profile parameters such as: P, La and must

be precisely matched to the workpiece material properties.

Profile G (Universal)

Standard form for most material types, particularly for materials General use, for alloys and stainless steel.

with a tendency to shrink. Recommended for high precision This profile eliminates the problem of the tool sticking

bore tolerance and straightness. Maintains precise exit hole in the hole after the outer corner dulls. Especially

size. Recommended when extra burnishing is required. suitable for crankshaft and other forged materials.

Recommended for accurate hole straightness.

Profile A

Profile H

Suitable for cast iron (usually coated) and aluminum alloys. Recommended for all nonferrous and cast iron

Can be used for cross drilling, angular entry or exit and materials up 5 mm diameter. Sometimes used for

for interrupted cut. Large coolant gaps between pads. wood and plastic with larger back taper.

Profile B Profile I

Excellent size control, for high precision hole tolerance.

Used for cast iron and aluminum alloys.

Used for aluminum and brass for best hole finish.

For intersecting holes and interrupted cut or when extra

outer diameter support and burnishing is required.

300 ISCAR