Page 215 - MILLING CATALOG p319-550

P. 215

IW7 CH Rd°

IS35

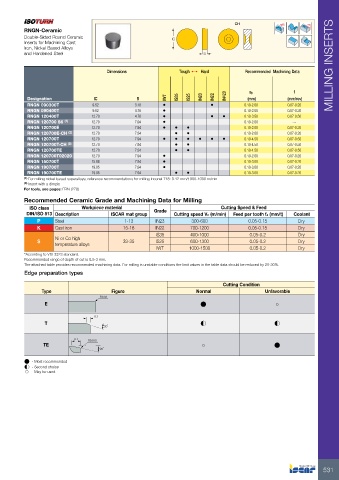

RNGN-Ceramic IS25IC

Double-Sided Round Ceramic IN23 S

Inserts for Machining Cast IN22

Iron, Nickel Based Alloys IN420Tough 1 Hard

and Hardened Steel

MILLING INSERTS

Dimensions Recommended Machining Data

Designation IC S • ap f

3.18 •

RNGN 090300T 9.52 4.76 • (mm) (mm/rev)

RNGN 090400T 9.52 4.76 • • •

RNGN 120400T 12.70 7.94 • • 0.10-2.00 0.07-0.20

RNGN 120700 S6 (1) 12.70 7.94 • • • 0.10-2.00 0.07-0.20

RNGN 120700E 12.70 7.94 • • 0.10-3.50 0.07-0.50

RNGN 120700E-CH (2) 12.70 7.94 • • • • • 0.10-2.00

RNGN 120700T 12.70 7.94 • • 0.10-2.00 ---

RNGN 120700T-CH (2) 12.70 7.94 • • 0.10-2.00 0.07-0.20

RNGN 120700TE 12.70 7.94 • 0.10-4.50 0.07-0.20

RNGN 120700T02020 12.70 7.94 • 0.10-4.50 0.07-0.50

RNGN 150700T 15.88 7.94 • 0.10-4.50 0.07-0.50

RNGN 190700T 19.05 7.94 • • 0.10-2.00 0.07-0.50

RNGN 190700TE 19.05 0.10-3.00 0.07-0.20

0.10-3.00 0.07-0.20

0.10-3.00 0.07-0.20

0.07-0.20

(1) For milling nickel based superalloys; reference recommendations for milling Inconel 718: 0.12 mm/t 900-1000 m/min

(2) Insert with a dimple

For tools, see pages: FRN (278)

Recommended Ceramic Grade and Machining Data for Milling

ISO class Workpiece material Grade Cutting Speed & Feed

Cutting speed Vc (m/min) Feed per tooth fz (mm/t)

DIN/ISO 513 Description ISCAR mat group Coolant

Dry

P Steel 1-13 IN23 300-600 0.05-0.15 Dry

Dry

K Cast iron 15-18 IN22 700-1200 0.05-0.15 Dry

Dry

S Ni or Co high 33-35 IS35 400-1000 0.05-0.2

temperature alloys IS25 600-1300 0.05-0.2

IW7 1000-1500 0.05-0.2

*According to VDI 3323 standard.

Recommended range of depth of cut is 0.5-3 mm.

The attached table provides recommended machining data. For milling is unstable conditions the limit values in the table data should be reduced by 20-30%.

Edge preparation types

Type Figure Normal Cutting Condition

E Unfavorable

R0.03

0.1

T

20

0.1 R0.015

TE

20

- Most recommended

- Second choice

- May be used

531