Page 228 - MILLING CATALOG p319-550

P. 228

MILLING INSERTS USER GUIDE

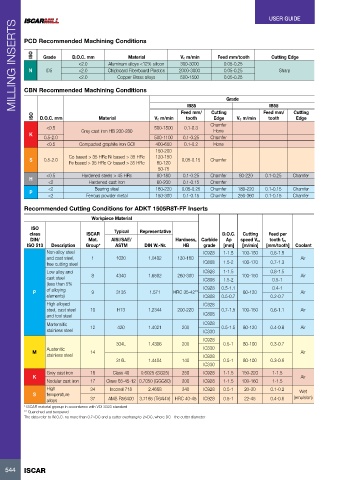

ISO ISOPCD Recommended Machining Conditions

Grade D.O.C. mm Material Vc m/min Feed mm/tooth Cutting Edge

N ID5 <2.0 Aluminum alloys <12% silicon 300-3000 0.05-0.25 Sharp

<2.0 Chipboard Fiberboard Plastics 2000-3000 0.05-0.25

<2.0 500-1500 0.05-0.25

Copper Brass alloys

CBN Recommended Machining Conditions

Grade

D.O.C. mm Material Vc m/min IB85 Cutting Vc m/min IB55 Cutting

Grey cast iron HB 200-280 Feed mm/ Edge Feed mm/ Edge

<0.5 Compacted graphite iron GCI 500-1500

K 0.5-2.0 tooth Chamfer tooth Chamfer

500-1100 0.1-0.3 Hone Chamfer

<0.5 400-600 0.1-0.25 Chamfer

150-200 0.1-0.2 Chamfer

120-150

60-120 0.05-0.15 Hone

S 0.5-2.0 Co based > 35 HRc Ni based > 35 HRc 50-75 0.1-0.25 Chamfer

Fe based > 35 HRc Cr based > 35 HRc 80-180 0.1-0.15

80-200 0.05-0.25

H <0.5 Hardened steels > 45 HRc 180-220 0.1-0.15 Chamfer 80-220 0.1-0.25

<2 Hardened cast iron 150-300 Chamfer

Bearing steel Chamfer 180-220 0.1-0.15

P <2 Chamfer 250-360 0.1-0.15

<2 Ferrous powder metal

Recommended Cutting Conditions for ADKT 1505R8T-FF Inserts

Workpiece Material

ISO Description ISCAR Typical Representative Hardness, Carbide D.O.C. Cutting Feed per Coolant

class Mat. AISI/SAE/ DIN W.-Nr. HB grade Ap speed Vc, tooth fz, Air

DIN/ Group* 1.0402 IC928 [m/min] [mm/tooth]

ISO 513 ASTM 130-180 [mm] 100-150 0.8-1.5 Air

1 IC808 1-1.5 100-170 Air

Non-alloy steel 1020 100-150 0.7-1.3

1.5-2

and cast steel, 80-120 0.8-1.5

0.5-1

free cutting steel 100-150 0.4-1

0.2-0.7

Low alloy and 8 4340 1.6582 260-300 IC928 1-1.5 80-120

9 3135 1.571 HRC 35-42** IC808 1.5-2

cast steel IC928 0.5-1.1 80-100

IC808 0.5-0.7

(less than 5% 80-100

150-220

P of alloying 100-160

elements)

20-30

High alloyed 10 H13 1.2344 200-220 IC928 22-45 0.6-1.1 Air

steel, cast steel IC808 0.7-1.5

and tool steel

Martensitic 12 420 1.4021 200 IC928 0.5-1.5 0.4-0.8 Air

stainless steel IC330

Austenitic 304L 1.4306 200 IC928 0.5-1 0.3-0.7

stainless steel 316L 1.4404 IC330

M 14 0.3-0.6 Air

IC928

140 IC330 0.5-1 1-1.5 Air

1-1.5 Wet

K Grey cast iron 16 Class 40 0.6025 (GG25) 250 IC928 1-1.5 0.1-0.2 (emulsion)

Nodular cast iron 17 Class 65-45-12 0.7050 (GGG50) 200 IC928 1-1.5 0.4-0.6

High 34 Inconel 718 2.4668 340 IC928 0.5-1

S temperature 0.5-1

37 AMS R56400 3.7165 (Ti6Al4V) HRC 40-45 IC928

alloys

* ISCAR material grpoup in accordance with VDI 3323 standard

** Quenched and tempered

The data refer to W.O.C. no more than 0.7×DC and a cutter overhang to 2×DC, where DC - the cutter diameter

544 ISCAR