Page 115 - TURNING CATALOG p121-254

P. 115

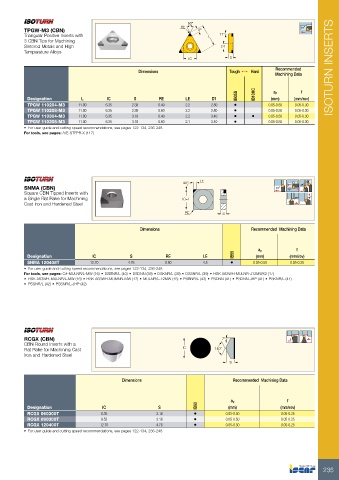

TPGW-M3 (CBN) 60° IB05S 91º

Triangular Positive Inserts with RE IB10HC

3 CBN Tips for Machining Recommended

Sintered Metals and High LE ISOTURN INSERTSMachining Data

Temperature Alloys

L 11°

D1

IC

S

Dimensions

Tough 1 Hard

ap f

Designation L IC S RE LE D1 (mm) (mm/rev)

2.2 2.80 •

TPGW 110204-M3 11.00 6.35 2.38 0.40 2.2 2.80 • 0.05-0.50 0.05-0.30

TPGW 110208-M3 11.00 6.35 2.38 0.80 • • 0.05-0.50 0.05-0.30

TPGW 110304-M3 11.00 6.35 3.18 0.40 2.2 3.40 0.05-0.50 0.05-0.30

2.1 3.40 •

TPGW 110308-M3 11.00 6.35 3.18 0.80 0.05-0.50 0.05-0.30

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/E-STFPR-X (117)

SNMA (CBN) 90° LE 75º 75º 45º

Square CBN Tipped Inserts with IC=L 45º

a Single Flat Rake for Machining

Cast Iron and Hardened Steel RE 45° 75º

S

Dimensions Recommended Machining Data

IB55 ap f

Designation IC S RE LE (mm) (mm/rev)

4.5 • 0.05-0.50 0.05-0.30

SNMA 120408T 12.70 4.76 0.80

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: C#-MULNR/L-MW (16) • DSBNR/L (40) • DSDNN (39) • DSKNR/L (39) • DSSNR/L (39) • HSK A63WH-MULNR-J12MWX2 (17)

• HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PSBNR/L (43) • PSDNN (41) • PSDNN-JHP (41) • PSKNR/L (41)

• PSSNR/L (42) • PSSNR/L-JHP (42)

RCGX (CBN) IC 7°

CBN Round Inserts with a 140°

Flat Rake for Machining Cast •

Iron and Hardened Steel • S

•

Dimensions Recommended Machining Data

Designation IC S IB90 ap f

RCGX 060300T 6.35 3.18 (mm) (mm/rev)

RCGX 090300T 9.52 3.18 0.05-0.50 0.05-0.25

RCGX 120400T 12.70 4.76 0.05-0.50 0.05-0.25

0.05-0.50 0.05-0.25

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

235